Executive Summary

On Saturday, February 15, 2014, about 11:30 a.m. local time,

a 2004 Kia Sorento sport utility vehicle (SUV), occupied by a 37-year-old

driver and four passengers, was traveling westbound on US Route 90 (US-90) near

Centerville, Louisiana.

The SUV was traveling in the right lane at a

witness-estimated speed of 70 mph (roadway speed limit) when the driver lost control

of the vehicle due to a tread separation and rapid air loss in the left rear

tire.

The SUV veered into the left westbound lane, rotating in a

counterclockwise direction, and departed the roadway into a 64-foot-wide

depressed earthen median.

It continued through the median, now rotating in a clockwise

direction; entered the eastbound traffic lanes of US-90; and collided with a

2005 IC Bus (66-passenger school bus), which was traveling in the right lane.

The left front of the SUV contacted the right front of the

school bus, resulting in the rapid clockwise rotation of the SUV and secondary

impacts along the right side of the school bus. The driver of the SUV and three

rear passengers were ejected. The fourth passenger remained in the vehicle.

Kia Left Rear Tire and Wheel

The left rear tire tread separated from the tire carcass

prior to the collision sequence.5 The left rear rim and tire carcass were still

attached to the Kia postcollision. The Louisiana State Police later removed

these components from the vehicle and transferred them to the NTSB materials

laboratory. NTSB investigators recovered the separated tread from the scene for

further examination.

The subject tire was a Michelin Cross Terrain manufactured

in late October 2003.6 The tire tread was composed of five ribs with zigzag

grooves between each rib. Tread depth measurements were taken in all four

grooves, every 4 inches along what would have been the circumference of the

tire (figure 4).

The average tread depths for grooves 1 through 4 were 4/32,

2/32, 2/32, and 3/32 inch, respectively.7 The tire had minimum tread depth

values of zero at some locations (bald spots), where wear had exceeded the

depth of the grooves.8

The state of Louisiana requires vehicle inspections every 2

years. The inspection requires that tires have at least 2/32 inch of tread

measured in any two adjacent tread grooves and that there are no knots, bulges,

sidewall cracks, or tread exposure. According to the Louisiana Office of Motor

Vehicles, the Kia passed inspection on April 11, 2013.

The tread separated from the tire carcass near a bald spot

located toward the inboard edge of the tire. The separation started as a

delamination between the inner and outer steel belts on the inboard side of the

tire. It evolved into a thumbnail-shaped pocket that extended along the

shoulder of the tire.

The difference in wear between the delaminated region and

the remainder of the tread indicates that the pocket was likely present for

several hundreds to thousands of miles. Additional delamination formed along

the outboard shoulder and progressed toward the inboard shoulder. The tread

separated from the tire when the delaminations merged. The tire carcass

subsequently split in the radial direction (from the outboard shoulder to the

inboard shoulder), and the tire lost pressure (figure 5).

Three foreign objects had penetrated the tread and the outer

steel ply. Figure 6 shows one object found approximately 46 inches clockwise

from the tip of the leading edge flap.9 The steel wires in the outer ply were

deformed where the objects had penetrated the tread.

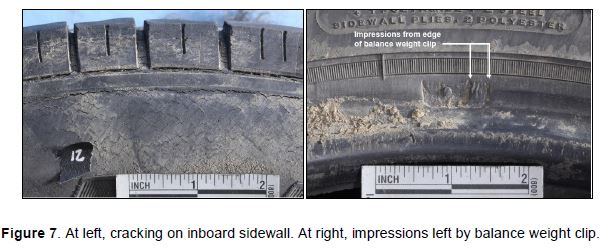

Other physical damage to the subject tire included U-shaped

compression set marks on the outboard sidewall and cracking along the sidewall,

buttress, and shoulder area (figure 7, left).10 The wheel weight clip, used to

balance the tire, left multiple impression marks near the bead on the inboard

side of the tire (figure 7, right), indicating that the tire had likely been

operated in an underinflated condition at some point during its lifetime. No

precollision damage was found on any of the rims.

Driver Information

Kia Driver

At the time of the crash, the driver of the Kia was

traveling from her home in Patterson, Louisiana, to the “Krewe of Head Start

Recruitment Parade” in Franklin. She held a class E driver’s license.15 According

to relatives, her vision, hearing, and general health were good. NTSB

investigators examined cell phone provider records and determined that she was

not using her cell phone at the time of the crash. Postcrash toxicological

testing did not indicate the presence of alcohol or drugs.16

According to the surviving passenger in the Kia, after the

tire failure, the vehicle drifted to the left and the driver responded by

braking and steering. According to a truck driver traveling behind the SUV,

when the tire “popped,” the vehicle moved to the right, then overcorrected to

the left, and crossed the median.

Field tests have found that drag forces are generated when a

rear tire experiences tread separation. These forces pull the vehicle toward

the side of the affected tire.17 Noise and vibration were present in each field

test before the vehicle began pulling to the side of the affected tire,

providing an auditory cue to the driver. In most cases, experienced test

drivers were able to keep the vehicle in the travel path with small steering

corrections.18

In other cases, the drag forces were significant and resulted in

large vehicle deviations.19 Other tests have reported that a higher vehicle

speed and a longer duration of the tread separation are associated with greater

lateral deviation from the travel path.20 Tests have also found that drag

forces ended once the tread fully separated from the tirewhereas, for a

partial tread separation, drag forces continued until the vehicle came to rest.

If the affected tire lost air, drag forces also continued until the vehicle

came to rest.21

Although an experienced test driver in a simulated

environment who is aware of an impending failure may be able to control a

vehicle following a tread separation, it can be difficult for a typical driver

to have the same control in some real-world traffic environments.

A rear tread

separation at high speed reduces the lateral forces generated by the rear

tires, which can result in excessive rotation and lateral motion for a given

steer input. These changes in vehicle response and maneuverability

characteristics can make it difficult for a driver to safely steer following a rear

tread separation. In addition, drag forces could lead a driver to respond in a

manner that further destabilizes the vehicle, resulting in a loss of control.22

The Louisiana Office of Motor Vehicles provides guidelines

for new and current class D and E drivers on how to respond to a tire blowout,

including staying calm, firmly holding the steering wheel and maintaining the

vehicle in the same lane (noting that there may be a strong pull from the right

or the left), slowing the vehicle, gently applying the brakes, and pulling off

the road to a safe area.

Probable Cause

The National Transportation Safety Board determines that the

probable cause of the Centerville, Louisiana, crash was the Kia SUV driver’s

loss of control due to the tread separation and rapid air loss of the left rear

tire, which altered vehicle handling characteristics.

Contributing to the crash was the deteriorated condition of

the tire due to inadequate maintenance.

Footnotes/References

5 The portion of the tire designed to contact the road

surface (tire tread) separated from the rubber-bonded cord structure of the

tire (tire carcass).

6 Michelin Cross Terrain P245/70R16 106H; tire

identification number: DOT 0CBU JDWX 4403.

7 The original tread depth for the subject tire, according

to manufacturer literature, was 11/32 inch.

8 The minimum tread depth values measured for the left

front, right front, and right rear tires were 11/32, 11/32, and 4/32 inch,

respectively.

9 The leading edge flap is the side of the tread that forms

a triangular wedge of tread pointing toward the direction of rotation, as shown

in figure 4.

10 Cracking can be associated with overdeflection, foreign

materials, ozone deterioration, loss of rubber elasticity over time, and

temperature.

11 At the time of inspection, the driver’s seat belt was

buckled and the seat belt webbing showed cloth color transfer, scuffing, and

cupping. The front seat passenger seat belt showed heat abrasion to the

webbing.

12 If seatback failure occurs, use of the restraint system

may not prevent the occupant from being ejected from the vehicle. See TES

Limited. 1989. Accidents Involving Seatback Failures, report no. C1322/2,

prepared for Transport Canada. Bedford, UK.

13 Louisiana Rev Stat §32.295.1 (www.legis.la.gov).

14 Louisiana Rev Stat §32.295 (www.legis.la.gov).

15 A class E license is a personal vehicle license and

permits the operation of any single motor vehicle under 10,000 pounds gross

vehicle weight rating.

16 Blood was tested for ethanol, acetone, isopropanol, and

methanol. Blood was screened for amphetamines, antidepressants, barbiturates,

benzodiazepines, cannabinoids, cocaine/metabolites, lidocaine, methadone,

nonopiate narcotic analgesic, opiates, phencyclidine, phenothiazines,

propoxyphene, acetaminophen, salicylates, oxycodone, fentanyl, and oxymorphone.

17 C. P. Dickerson, M. W. Arndt, and S. M. Arndt. 1999.

“Vehicle Handling With Tire Tread Separation,” paper no. 1999-01-0120. SAE

World Congress and Exhibition. Warrendale, Pennsylvania: SAE International.

18 R. F. Fay, R. D. Robinette, J. Smith, T. Flood, and G.

Bolden. 1999. “Drag and Steering Effects From Tire Tread Belt Separation and

Loss,” paper no. 1999-01-0447. SAE World Congress and Exhibition. Warrendale,

Pennsylvania: SAE International.

19 D. F. Tandy, K. T. Tandy, N. J. Durisek, K. J. Granat, R.

J. Pascarella, L. Carr, and R. Liebbe. 2007. “An Analysis of Yaw Inducing Drag

Forces Imparted During Tire Tread Belt Detachments,” paper no. 2007-01-0836. SAE

World Congress and Exhibition. Warrendale, Pennsylvania: SAE International.

20 S. M. Arndt and M. W. Arndt. 2001. “The Influence of a

Rear Tire Tread Separation on a Vehicle’s Stability and Control,” paper no.

258. Proceedings, 17th International Technical Conference on the Enhanced

Safety of Vehicles (ESV), Amsterdam, The Netherlands. Washington, DC: NHTSA.

21 G. Beauchamp, D. Koch, and D. E. Thornton. 2013. “A

Comparison of 25 High Speed Tire Disablements Involving Full and Partial Tread

Separations,” paper no. 2013-01-0776. SAE World Congress and Exhibition.

Warrendale, Pennsylvania: SAE International.

22 Loss of control can occur for a variety of reasons. For

the purpose of this report, “loss of control” refers to a change in vehicle

response characteristics beyond which a driver can adapt and steer along the

intended path.

23 See web01.dps.louisiana.gov/DPSForms.nsf, accessed June

12, 2015.

24 A class B license is a commercial driver’s license that

permits the operation of heavy straight vehicles. A straight vehicle is a

vehicle that does not bend or have a moveable joint in its frame between the

driver seat and the cargo or passenger compartment. The driver had the school

bus and passenger endorsements.