Agriculture ranks among the most hazardous industries. Farmers are at

very high risk for fatal and nonfatal injuries; and farming is one of

the few industries in which family members (who often share the work and

live on the premises) are also at risk for fatal and nonfatal injuries.

In 1990, NIOSH developed an extensive agricultural safety and health

program to address the high risks of injuries and illnesses experienced

by workers and families in agriculture. NIOSH supports intramural

research and funds extramural research and prevention programs at

university centers in 10 states. These programs conduct research on

injuries associated with agriculture, as well as pesticide exposure,

pulmonary disease, musculoskeletal disorders, hearing loss, and stress.

Agriculture ranks among the most hazardous industries. Farmers are at

very high risk for fatal and nonfatal injuries; and farming is one of

the few industries in which family members (who often share the work and

live on the premises) are also at risk for fatal and nonfatal injuries.

In 1990, NIOSH developed an extensive agricultural safety and health

program to address the high risks of injuries and illnesses experienced

by workers and families in agriculture. NIOSH supports intramural

research and funds extramural research and prevention programs at

university centers in 10 states. These programs conduct research on

injuries associated with agriculture, as well as pesticide exposure,

pulmonary disease, musculoskeletal disorders, hearing loss, and stress.

Who’s at Risk?

- Approximately 1,854,000 full-time workers were employed in production agriculture in the US in 2012.

- Approximately 1.4 to 2.1 million hired crop workers are employed annually on crop farms in the US.

- An estimated 955,000 youth under 20 years of age resided on farms in

2012, with about 472,000 youth performing farm work. In addition to the

youth who live on farms, an estimated 259,000 youth were hired to work

on US farms in 2012.

Fatalities

- In 2012, 374 farmers and farm workers died from a work-related

injury, resulting in a fatality rate of 20.2 deaths per 100,000 workers.

Tractor overturns were the leading cause of death for these farmers and

farm workers.

- The most effective way to prevent tractor overturn deaths is the use

of a Roll-Over Protective Structure (ROPS). In 2012, 59% of tractors

used on farms in the US were equipped with ROPS. If ROPS were placed on

all tractors used on US farms manufactured since the mid-1960’s, the

prevalence of ROPS-equipped tractors could be increased to over 80%.

- On average, 113 youth less than 20 years of age die annually from

farm-related injuries (1995 -2002), with most of these deaths occurring

to youth 16-19 years of age (34%).

- Of the leading sources of fatal injuries to youth, 23% percent

involved machinery (including tractors), 19% involved motor vehicles

(including ATVs), and 16% were due to drowning.

Injuries

- Every day, about 167 agricultural workers suffer a lost-work-time

injury. Five percent of these injuries result in permanent impairment.

- From 2008-2010, 50% of all hired crop worker injuries were classified as a sprain or strain.

- In 2012, an estimated 14,000 youth were injured on farms; 2,700 of these injuries were due to farm work.

A national occupational safety and health

agenda

for the agricultural production industry has been developed as part of the

National Occupational Research Agenda

(NORA) process. Further information on agriculture production safety and health is also available as part of the activities.

======================

Growing Hazards: Safety Rules Often Don’t Apply To Farming, One Of The Most Dangerous Jobs

By Nicole Erwin

May 26, 2017

Jeanna Glisson has two lives: her life before August 20th, 2007, and her life after. That day is so vivid, Glisson can still hear the sounds of her son’s feet coming down the stairs.

“I remember Derek when he got up that morning, he was on the phone talking to my dad. He was excited,” Glisson said.

It was the first day of harvest at Swift Farms in Murray, Kentucky, and Derek couldn’t wait to get to the corn fields. Glisson remembers it feeling like the hottest day of the year. It was a Monday, she said.

“He looked forward to it. I remember him getting in the shower. And then after that…” Her voice trails off. She remembers that the phone rang. It was her brother. Derek had been hurt. Before Glisson or any of the emergency responders could get to the farm, it was too late.

Courtesy Jeanna Glisson

Courtesy Jeanna Glisson

Derek Glisson as a young boy, with his father.

“He was dead on arrival,” she said.

Just hours before, Derek, his grandfather, and a couple other farm workers had been trying to reattach a piece of equipment to a combine. They had gone through the motions to make sure the part was attached, even lifting the piece three times before Derek crawled under the machine. But somehow, the equipment slipped.

“It was a tragic, tragic accident is the best way I can explain it. I don’t think there was one thing they could have done differently,” Glisson said.

On her way through the flashing emergency lights and long line of neighbors along Faxon Road, Glisson finally made it to her son. “He looked peaceful, like he was asleep,” she said.

The Calloway County Coroner said Derek died from mechanical asphyxia from crushing injuries.

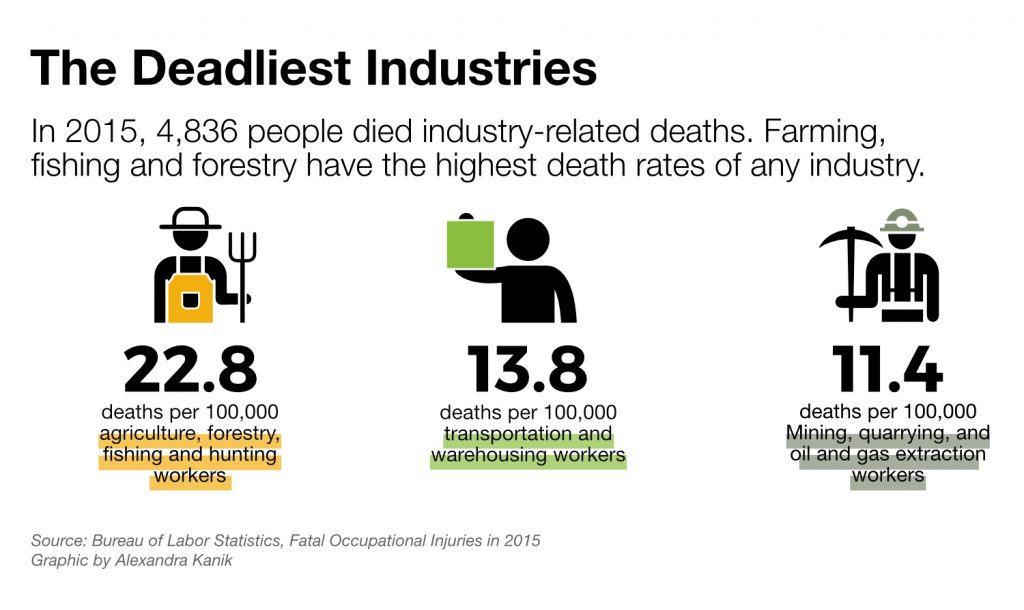

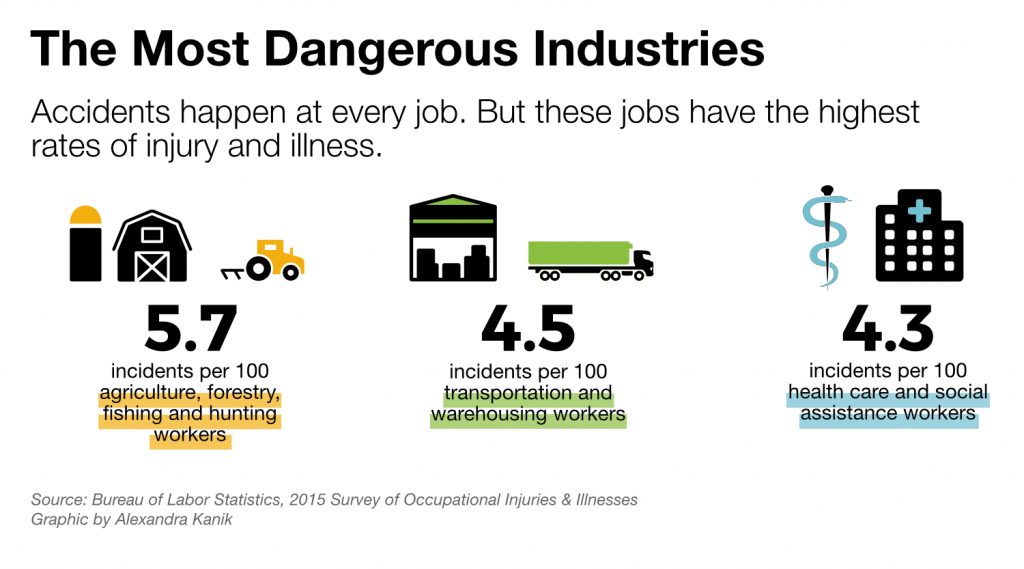

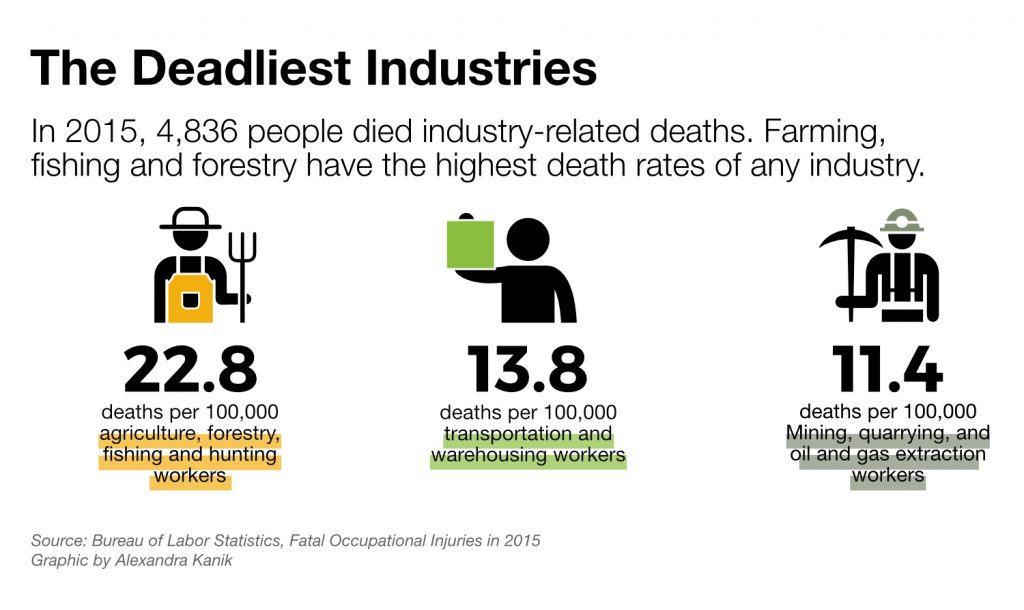

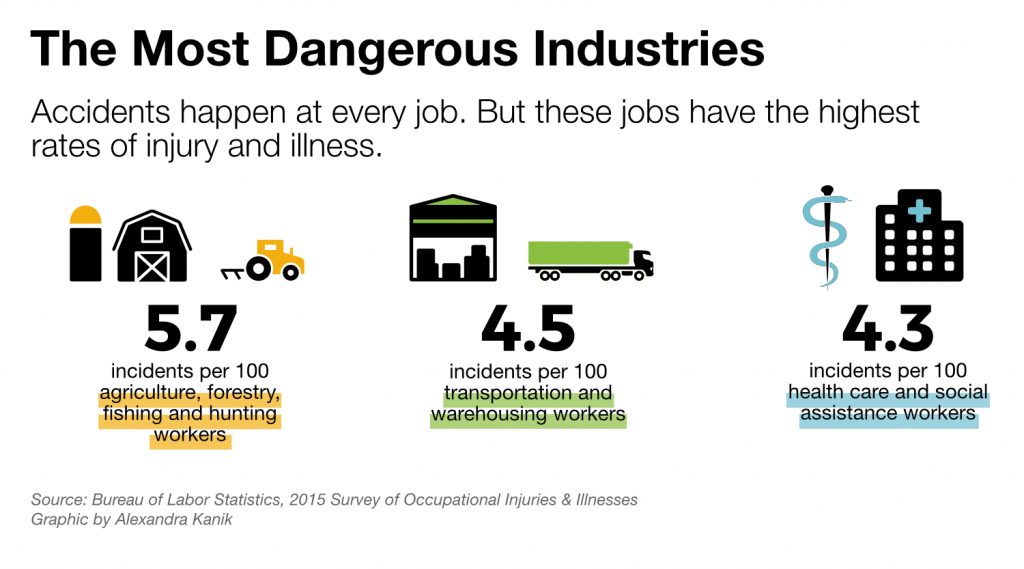

Farming is among the country’s most dangerous occupations. Government statistics show the industry consistently has some of the highest risks for injury and death from work-related accidents, and the Ohio Valley region is no exception.

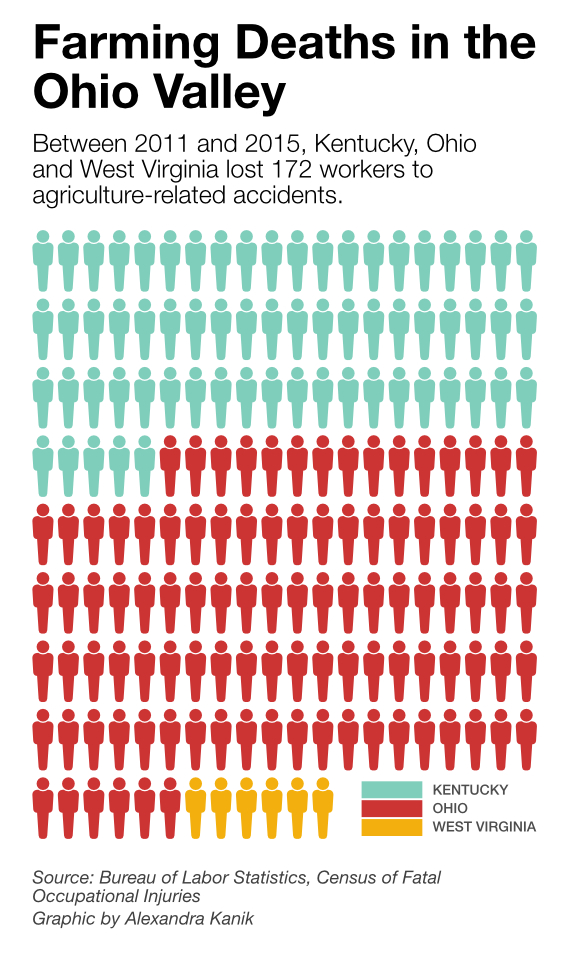

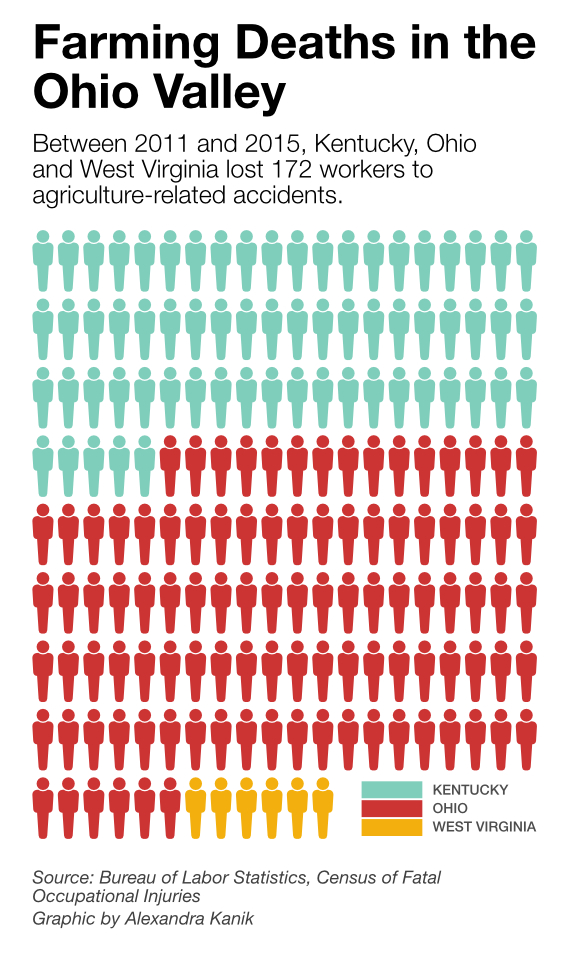

A ReSource review of data on agriculture-related deaths shows that from 2011 to 2015, Ohio had 101 fatalities, the fifth highest such number in the nation. Kentucky had 65 fatalities over those five years, the 14th highest in the nation. West Virginia, which has relatively few people in farming, had six fatalities.

Alexandra Kanik | Ohio Valley ReSource

Alexandra Kanik | Ohio Valley ReSource

Agribusiness leaders say voluntary training and awareness are improving safety. But veteran safety regulators say enforcement is also lacking. Unlike with other industries, safety regulators are restricted on what they can do to help when it comes to injuries and fatalities on the farm.

Farm Loophole

Jordan Barab is a former deputy assistant secretary of the Occupational Safety and Health Administration, or OSHA, who has been blogging on worker safety issues since leaving government at the end of the Obama administration. Barab said the agency faces frustrating limitations when it comes to farms, especially small farms, which statistics show are generally more hazardous.

“Basically, OSHA is not allowed to go on any small farm,” he said. “And that means for any reason.”

“Small” is defined as having fewer than 11 workers other than family members and no migrant labor housed on the farm.

Barab said this loophole in worker safety for small farms exists because of the political sway of agriculture lobbyists, including the Farm Bureau.

“If there is a worker complaint, if a worker gets killed, if ten workers get killed, OSHA can’t even step foot on there to cite or anything,” he said.

A lot of people get hurt and killed on farms and Barab said it’s because of the nature of the work environment. Risky activity, confined spaces such as grain silos, and dangerous, heavy machines are all areas where he thinks inspectors could be helpful.

“There are all kinds of issues on farms that OSHA could address,” he said.

Courtesy Jeanna Glisson

Courtesy Jeanna Glisson

Some of the heavy equipment at Swift Farms. Equipment accidents such as tractor roll-overs account for many farm injuries and deaths.

During Barab’s time at OSHA, he said, the department was often stopped in its tracks if it came close to issues regarding agriculture. In Barab’s blog “Confined Space” he wrote that agribusiness lobbyists accused his agency of “destroying the great American family farm” when it attempted what he considered common sense safety improvements:

When OSHA tried to protect workers — not through regulations, but through clarifications or new enforcement initiatives for existing regulations…when we were trying to save the lives of workers — often teen-age kids — from suffocating in grain silos, when we tried to correct a misinterpretation of OSHA’s Process Safety Standard to compel small fertilizer establishments (like West fertilizer that exploded in 2013, killing 15 people and leveling part of the town) to take basic precautions with hazardous materials that other chemical establishments were required to take.

Barab said OSHA offers more than just enforcement. Consultation services in every state allow for inspections to improve practices without penalty.

“There will always be employers who want to cut corners” said Barab, and that’s who needs enforcement.

Alexandra Kanik | Ohio Valley ReSource

Alexandra Kanik | Ohio Valley ReSource

Even getting accurate numbers on farming injuries and deaths can be frustrating. A study by the Ohio Commission on the Prevention of Injury found that “there is a gap in the fatality and injury reporting systems for the agricultural occupation.” With at least ten different sources of data on work-related safety incidents, “the United States does not have a unified reporting system.”

Farm Bureau spokesperson Paul Schlegal said bureau policies are decided by delegates from all fifty states at annual meetings. He said their consensus is that safety awareness works best through grassroots training efforts with local programs.

“I don’t think OSHA was set up to regulate safety on small farms,” he said. “And you have seen for literally decades a Congressional directive that supports that point of view, so I don’t think that is going to change.”

“Safety begins with each individual employer,” Schlegal said, and responsibility to follow safe working rules and conditions falls on the employees.

Future Farmers

Future Farmers of America provides some of this training. In the Ohio Valley the FFA has chapters with more than 45,000 students.

Kentucky FFA Executive Secretary Matt Chaliff said farm safety “seems to have renewed interest.” Just this year national FFA is moving to include safety as one of its “15 areas of interest” to drive safety awareness to all its member chapters. A new agreement with Safety in Agriculture for Youth will also provide online resources.

Chaliff said instilling safety awareness into behavioral practices is different when it comes to younger farmers who often exhibit what he calls an “invincibility” attitude. They tend to overestimate their abilities and underestimate risk. Add a four-wheel All Terrain Vehicle, or ATV, into the mix, and those risks increase significantly, he said

“We see a huge issue with ATV’s,” he said, noting the many injuries resulting from their use. “ATVs have become such a prevalent part in agriculture. It’s something we need to get a handle on.”

Life Lessons

Farmer and college student Brandon Pepper attended FFA classes before he graduated from LaRue County High School in Hodgenville, Kentucky. Last year, Pepper had a freak accident on the farm that he said resonated more than the FFA seminars ever could.

Alexandra Kanik | Ohio Valley ReSource

Alexandra Kanik | Ohio Valley ReSource

“My father and a couple of hired hands were working on a piece of tillage equipment out in the field,” Pepper said. His family repurposes old farm equipment as a small side business.

“We had a guy hitting metal with a hammer, and my father was running the torch, and I was running the bottle-jack, and putting a lot of pressure on this piece of metal that we were trying to move,” he said. “All of the sudden it moved very fast.”

Pepper said he didn’t realize what had happened until he looked down at his hand.

“My thumb,” he said, “was hanging by a little bitty piece of skin, I could have cut it off with a pair of fingernail clippers.” The thumb was spared, but the knuckle was not.

But even after nearly losing his thumb, Pepper still resists regulations. If he could turn back the clock and bring an agency like OSHA on the farm, he said, he wouldn’t.

“It makes things more difficult to do,” he said.

Pepper’s comments reflect a deep mindset in farming country, one that prizes independence and self-reliance and resents government intrusion. However, he is open to other ways of improving safety practices.

“If there was some kind of nonprofit organization that wasn’t going to come in and tell us what we could and could not do and just try and help us,” he said. “I feel like that could be beneficial.”

Putting Safety In Neutral

That is where organizations such as Ag Safe, a nonprofit farm training organization, can step in. Ag Safe started in California in 1991. This year Development Director Natalie Gupton opened an office in Kentucky.

“In our 26 years of existence we have yet to meet a farmer that wants something bad to happen to their workers,” Gupton said.

Gupton said Ag Safe offers a “neutral third party” for farmers who need better safety training and awareness and help managing the regulations they face. She expects the organization will likely expand to include Ohio and West Virginia as well. From proper pesticide use to updated farm equipment, she said, a myriad of compliance concerns that come with at least eight government organizations can overwhelm farmers.

“There’s so many organizations that a farmer has to deal with, big or small, when they’re working with our nation’s food supply,” Gupton said.

Gupton said she doesn’t think additional regulation is the right approach. She said communication often isn’t good among different government departments. That means rules can overlap and farmers can be confused on whether allowing one regulator on their fields could create a conflict with another agency limiting who can be among crops.

Courtesy Jeanna Glisson

Courtesy Jeanna Glisson

Cornfields at harvest time.

Because Ag Safe isn’t a regulator, farmers and insurance companies seem to welcome its presence.

“We’ve had stories from past clients that an issue happened on their farm but because they were involved with AG Safe the liability was waived. Because they had taken the measures and had established protocols and procedures in place, they were not found at fault,” Gupton said.

In some parts of farming country, insurance companies offer incentives for safety training. North Dakota, for instance, encourages farmers to enroll in specific training programs with a discount of up to 25 percent on annual premiums. No such incentives are available in the Ohio Valley.

Painful Reminders

Whether the solution lies in more voluntary programs, more enforcement efforts, or some combination, the numbers on farming’s risks indicate that more should be done to make farms safer for families and workers.

Jeanna Glisson lives with painful reminders of the lives those numbers represent. This summer marks the tenth anniversary of Derek’s death at age 21.

“We used to live in a world where you think bad things don’t happen,” she said. “And now we’re like, ‘bad things could be right around the corner at any given moment.’ So we try to stay more aware, we try to be more safety conscious, I believe.” Glisson has her own incentive plan for bringing awareness to young farmers. This August, she is organizing a tractor pull to raise awareness about the dangers of farming through a scholarship in Derek’s memory.

Hazards & Controls

What hazards are agricultural workers exposed to?

Farmworkers are exposed to numerous safety, health, environmental,

biological, and respiratory hazards. These include vehicle rollovers,

heat exposure, falls, musculoskeletal injuries, hazardous equipment,

grain bins, unsanitary conditions, pesticides, and many others.

VEHICLE HAZARDS

In 2011, vehicular accidents caused close to half (276) of the 570 fatalities in agriculture.1 Injuries from vehicular incidents are serious and debilitating to farm activities. For more information, visit the Vehicle Hazards page.

HEAT

Heat-related illness. HEAT ILLNESS CAN BE DEADLY. Every year, thousands of workers become sick from exposure to heat, and some even die. These illnesses and deaths are preventable.

Workers exposed to hot and humid conditions are at a high risk of

heat illness, especially if they are doing heavy work tasks or using

bulky protective clothing and equipment. New workers may also be at

greater risk than others if they have not built up a tolerance to hot

conditions. Employers must take steps to help workers become acclimated.

Prevention.

Heat-related illnesses, while potentially deadly, are easily

preventable. When working in hot conditions, remember "WATER, REST,

SHADE." Drink water every 15 minutes, even when not thirsty. Wear a hat

and light-colored clothing. Rest in the shade. Be sure to watch out for

fellow workers and know your location in case you need to call for

assistance. Get help right away if there are any signs of illness.

LADDERS & FALLS

Deaths and injuries from falls remain a major hazard for farmworkers.

- According to the Bureau of Labor Statistics (BLS), agricultural

workers had a non-fatal, fall-related injury rate of 48.2 per 10,000

workers in 2011—far higher than the same type of injury rates in the

transportation, mining or manufacturing industries.1

- Between 2007 and 2011 the BLS reported 167 agricultural workers' deaths were due to falls.1

Fall protection and ladder safety. OSHA's Fall Protection topics page and the National Institute of Occupational Safety and Health's Fall Injuries Prevention in the Workplace

site provide general information on different types of fall protection.

The following resources provide fall protection guidance for farm

workers and employers:

MUSCULOSKELETAL INJURIES

Workers in agricultural operations for both crop and animal

production typically use repetitive motions in awkward positions and

which can cause musculoskeletal injuries.2

Ergonomic risk factors

are found in jobs requiring repetitive, forceful, or prolonged

exertions of the hands; frequent or heavy lifting, pushing, pulling, or

carrying of heavy objects; and prolonged awkward postures. Vibration and

cold may intensify these conditions.

New technology may reduce some types of ergonomic injuries but

increase others. For instance, while dairy farmers have traditionally

been at a higher risk for developing osteoarthritis of the knee3,

more recent research has shown new technology used in milking has

resulted in a shift in musculoskeletal disorders to the shoulders, hands

and arms.

Ergonomic protections. Proper tools, padding to reduce vibration,

and fewer activities with high repetition are some methods for reducing

musculoskeletal injuries.4 The National Institute for Occupational Safety and Health's page on Ergonomics and Musculoskeletal Disorders provides general information on the topic. In addition, NIOSH's Simple Solutions: Ergonomics for Farmworkers

has information about early intervention to prevent these injuries for

growers, safety specialists, human resources managers or anyone with an

interest in safe farms.

HAZARDOUS EQUIPMENT AND MACHINERY

Farmworkers routinely use knives, hoes, and other cutting tools; work

on ladders; or use machinery in their shops. However, these simple

tools can be hazardous and have the potential for causing severe

injuries when used or maintained improperly.

- All tools should be maintained in good condition and used according to the manufacturers' instructions.

- Power tools must be properly grounded or double insulated and all guards or shields must be in place.

- Farmworkers should wear the proper personal protective equipment

(PPE) and make sure that clothing has no strings or loose ends that

could be caught by machinery. Long hair should be tied back to prevent

entanglement.

- In addition, shops should be well lit and have clear walkways to eliminate slips, trips and falls.

GRAIN BINS AND SILOS

While safety issues surrounding grain bins and silos are sometimes

overlooked on farms, they pose many dangers. Farmworkers are exposed to

suffocation or engulfment hazards when working with grain bins and

silos, as well as grain dust exposures and explosions. Suffocation is a

leading cause of death in grain storage bins. In 2010, the number of

workers engulfed by grain stored in bins hit a record high of 57

engulfments and 26 deaths. As a direct result, OSHA issued a Hazard Alert and an illustrated hazard wallet card*

explaining the dangers of working inside grain storage bins. In 2012,

19 workers were engulfed by grain stored in bins, and 8 died.5

Suffocation can occur when a worker becomes buried (engulfed) by

grain as they walk on moving grain or attempt to clear grain built up on

the inside of a bin. Moving grain acts like "quicksand" and can bury a

worker in seconds. "Bridged" grain and vertical piles of stored grain

can also collapse unexpectedly if a worker stands on or near it.

Additional information on safety and health issues associated with grain

handling, such as personal protective equipment, use of lifelines,

lockout/tagout, and training is located on the OSHA Grain Handling Safety and Health Topics Page.

UNSANITARY CONDITIONS

The lack of drinking water, sanitation facilities and/or handwashing

facilities can lead to many health effects. Farmworkers may suffer heat

stroke and heat exhaustion from an insufficient intake of potable water,

urinary tract infections due to urine retention from inadequate

availability of toilets, agrichemical poisoning resulting from lack of

handwashing facilities, and infectious and other communicable diseases

from microbial and parasitic exposures.

The Field Sanitation standard

(1928.110) applies to any agricultural establishment where eleven (11)

or more workers are engaged on any given day in hand-labor operations in

the field. OSHA standards require covered employers to provide:

toilets, potable drinking water, and hand-washing facilities to

hand-laborers in the field; to provide each worker reasonable use of the

above; and to inform each worker of the importance of good hygiene

practices.

PESTICIDES AND OTHER CHEMICALS

Pesticide exposure. Pesticides pose risks of short- and

long- term illness to farmworkers and their families. Workers who mix,

load or apply pesticides (known as pesticide handlers) can be exposed to

toxic pesticides due to spills and splashes, defective, missing or

inadequate protective equipment, direct spray, or drift. Workers who

perform hand labor tasks in areas that have been treated with pesticides

face exposure from direct spray, drift or contact with pesticide

residues on the crop or soil.

Pesticides can present a hazard to applicators, to harvesters

reentering a sprayed field, to family members due to take-home

contamination, and to rural residents via air, ground water and food.

Workers may be exposed to pesticides in a variety of ways, including:

working in a field where pesticides have recently been applied;

breathing in pesticide "drift" from adjoining or nearby fields; working

in a pesticide-treated field without appropriate PPE; eating with

pesticide-contaminated hands; eating contaminated fruits and vegetables;

and eating in a pesticide-contaminated field. Workers may also be

exposed to pesticides if they drink from, wash their hands, or bathe in

irrigation canals or holding ponds, where pesticides can accumulate.

Pesticide protection. The Environmental Protection Agency (EPA) oversees pesticide use through the Worker Protection Standard (WPS).

The WPS is a regulation for agricultural pesticides which is aimed at

reducing the risk of pesticide poisonings and injuries among

agricultural workers and pesticide handlers. The WPS protects employees

on farms, forests, nurseries, and greenhouses from occupational exposure

to agricultural pesticides. The regulation covers two types of workers:

- Pesticide handlers -- those who mix, load, or apply

agricultural pesticides; clean or repair pesticide application

equipment; or assist with the application of pesticides in any way.

- Agricultural workers -- those who perform tasks related to

the cultivation and harvesting of plants on farms or in greenhouses,

nurseries, or forests. Workers include anyone employed for any type of

compensation (including self-employed) doing tasks -- such as carrying

nursery stock, repotting plants, or watering -- related to the

production of agricultural plants on an agricultural establishment.

Workers do not include office employees, truck

drivers, mechanics, and any others not engaged in handling,

cultivation, or harvesting activities.

The WPS contains requirements for pesticide safety training,

notification of pesticide applications, use of personal protective

equipment, restricted-entry intervals after pesticide application,

decontamination supplies, and emergency medical assistance. While EPA

covers the use of respirators in the application of pesticides, OSHA's

Safety and Health Topic page on Respiratory Protection provides general information on respirator use and OSHA standards that may apply with the use of other chemicals.

Hazard Communication.

Chemicals must be properly labeled so farmworkers know the identity and

hazards of the chemicals they may be exposed to at work. OSHA has information

to assist employers and workers ensure that hazard communication is

properly addressed in their workplaces. In addition, certain OSHA standards address hazard communications. As explained in 1910.1200(b)(5)(i), pesticides covered under FIFRA are exempt from the OSHA labeling requirements since EPA regulates these labels.

RESPIRATORY DISTRESS

Respiratory hazards. Respiratory hazards. Respiratory

hazards in barns, manure pits, machinery and silos range from acute to

chronic air contaminants. Farmworkers' most common respiratory hazards

are bioaerosols, such as organic dusts, microorganisms, and endotoxins

and chemical toxicants from the breakdown of grain and animal waste.

Inorganic dust, from silicates in harvesting and tilling, is prevalent

but less significant.6

Changes to farming mechanisms have both improved working conditions

and increased exposure to respiratory hazards—mainly due to the

increased density in animal confinement.6

Respiratory protection.

Control of aerosols might include the enclosure and ventilation of

tractors, applying moisture to friable material, and respirators.6

Helpful links include:

ZOONOTIC INFECTIONS & RELATED HAZARDS

Zoonoses are infectious diseases common to animals and humans. As new

infections evolve, the numbers and types of zoonoses change. More

recent types of these infections include avian flu,

methicillin-resistant Staphylococcus aureus (MRSA) and West Nile virus.

The agricultural worker's risk of acquiring a zoonotic infection varies

with the type and species of animal and the geographic location.

The National Association of State Public Health Veterinarians, Veterinary Infection Control Committee* have identified several methods to prevent zoonotic infections, including:

- Personal protective actions and equipment, such as, hand hygiene,

the use of appropriate gloves and outer protection, facial and

respiratory protection and the tracking of aggressive animals, so that

restraints are used when necessary.

- Environmental infection control, such as cleaning and disinfecting

surfaces and equipment, vaccinating healthy animals, isolating diseased

animals, disposing of infected tissues or dead animals appropriately and

controlling the infestation of pests which can be a carrier of these

infections.

- Worker health, such as vaccinating workers and providing proper training.

Worker health, such as vaccinating workers and providing proper training.7 Worker health, such as vaccinating workers and providing proper training. The National Association of State Public Health Veterinarians, Veterinary Infection Control Committee* have identified several methods to prevent needlestick and related injuries, including:

- Having an approved sharps container,

- Never removing the needle cap with one's mouth,

- Avoiding the recapping of needles,

- Wearing the appropriate personal protection equipment, such as gloves.

NOISE

Thousands of workers every year suffer from preventable hearing loss

due to high workplace noise levels, and research has shown that those

who live and work on farms have had significantly higher rates of

hearing loss than the general population.8 In fact, farming is among the occupations recognized as having the highest risks for hearing loss.9

Tractors, forage harvesters, silage blowers, chain saws, skid-steer

loaders, grain dryers, squealing pigs and guns are some of the most

typical sources of noise on the farm. Studies suggest that lengthy

exposure to these high sound levels have resulted in noise-induced

hearing loss to farmworkers of all ages, including teenagers. Hearing

loss is not as dramatic nor as sudden as an injury from a tractor

overturn or machine entanglement, but it is permanent.

Employers can achieve noise reduction in several ways - usually related to the maintenance of the equipment:

- Worn, loose, or unbalanced machine parts can increase decibel levels

during operation. Regular lubrication and parts replacement (bearings,

mufflers, silencers, etc.,) reduce friction and lower noise levels.

- Larger engines that can be operated at lower speeds reduce noise levels, and may even conserve fuel.

- Vibration isolation pads may be installed under the legs of noisy

equipment to reduce noise generated by the equipment vibrating on a

cement floor.

- Newer chainsaws and leaf blowers have flexible mountings to reduce vibration-induced noise as well.

- Tractor and skid-steers can be purchased with sound reducing cabs

and tightly fitted cab doors and windows to reduce how much outside

noise reaches the operator.

- Acoustical materials may be installed on walls and ceilings to enclose sound.

In addition, employers may provide workers with personal protective

equipment (PPE) but must train them in using the PPE correctly. OSHA's

Safety and Health Topics Page on PPE describes proper use of personal protective equipment.

Noise and Hearing Conservation - OSHA's Safety and Health Topics Page on Occupational Noise Exposure provides a comprehensive review of the hazards of noise, the means of protection, as well as OSHA requirements.

OTHER HAZARDS

Farmworkers may face a number of other hazards due to being outside.

The National Institute for Occupational Safety and Health's (NIOSH's)

Workplace Safety and Health Topics page on Hazards to Outdoor Workers includes information on:

- Other Biological Hazards. These include vector-borne diseases, venomous wildlife and insects, and poisonous plants.

- Extreme Cold.

- Lightning.

- Ultraviolet Radiation.

Confined Space. Besides grain storage, farmworkers face dangers in entering other confined spaces such as:

A NIOSH Alert publication,

Preventing Deaths of Farm Workers in Manure Pits, provides basic

guidance. In addition, OSHA's Safety and Health Topics page on Confined Space, provides further guidance on different types of confined spaces.

Skin Disorders. Workers in the agricultural sector are at

risk of potentially harmful exposures of the skin. The NIOSH Workplace

Safety & Health Topics page on Skin Exposures & Effects provides information on the different types of exposures and the associated hazards.

Electrical Hazards. Electrical hazards in agriculture range

from the dangers of hitting overhead wires when using large equipment to

the possibility of hitting underground wires when digging. OSHA's page

on Electrical Safety and the NIOSH Workplace Safety & Health Topics page on Electrical Safety provide resources on preventing a range of electrical accidents.

1 Bureau of Labor Statistics (BLS), United States

Department of Labor. Occupational Injuries and Illnesses and Fatal

Injuries Profiles database queried by industry for Agriculture,

Forestry, Fishing and Hunting (GP2AFH), Accessed June 2013.

2 Kirkhorn, S.R., Earle-Richardson, G., Banks,

R.J., "Ergonomic Risks and Musculoskeletal Disorders in Production

Agriculture: Recommendations for Effective Research to Practice." Journal of Agromedicine, 15:281-299, 2010. Davis KG, Kotowski SE, "Understanding the ergonomic risk for musculoskeletal disorders in the United States agricultural sector." American Journal of Industrial Medicine, 50(7):501-511, 2007. Douphrate, D.I., Nonnenmann, M.W., Rosecrance, J.C., "Ergonomics in Industrialized Dairy Operations." Journal of Agromedicine, 14:406-412, 2009.

3 Nonnenmann, M.W., Anton, D.C., Gerr, F., Yack,

H.J., "Dairy Farm Worker Exposure to Awkward Knee Posture During

Milking and Feeding Tasks." Journal of Occupational and Environmental Hygiene, 7:483-489, 2010.

4 Cook, K.E., Field, W.E., "Proceedings of the

'Arthritis, Agriculture, and Rural Life: State of the Art Research

Practices, and Applications' Conference", West Lafayette, Indiana, May

11-13, 2011. Journal of Agromedicine, 16:311-318, 2011.

5 Issa, S., Roberts, M., Field, B., 2012 Summary of Grain Entrapments in the United States. Purdue University.

6 Kirkhorn, S.R., Garry, V.F., "Agricultural Lung Diseases." Environmental Health Perspectives, 108(4):705-712, 2000.

7 Langley, R., Morgan, W.E., "Livestock Handling-Minimizing Worker Injuries." Journal of Agromedicine, 2010 July; 15(3):226-35.

8 Ehlers, J.J, Graydon, P.S., "Noise-induced

hearing loss in agriculture: Creating partnerships to overcome barriers

and educate the community on prevention." Noise & Health, March-April 2011, 13:51, 142-46.

9 Sliwinska-Kowalska M, Davis A., "Noise-induced hearing loss." Noise Health [serial online], 2012;14:274-80.

Courtesy Jeanna Glisson

Courtesy Jeanna Glisson  Alexandra Kanik | Ohio Valley ReSource

Alexandra Kanik | Ohio Valley ReSource  Courtesy Jeanna Glisson

Courtesy Jeanna Glisson  Alexandra Kanik | Ohio Valley ReSource

Alexandra Kanik | Ohio Valley ReSource  Alexandra Kanik | Ohio Valley ReSource

Alexandra Kanik | Ohio Valley ReSource  Courtesy Jeanna Glisson

Courtesy Jeanna Glisson