Matt Bell/Register & Bee

The Goodyear plant in Danville

Posted: Friday, August 12, 2016 10:57 am

Danville Register & Bee

Another worker has died at Goodyear’s plant in Danville.

"We regret to report that early this morning, a death occurred in the Goodyear-Danville manufacturing facility," Goodyear spokeswoman Laura Singleton said in a statement Friday morning.

Goodyear's on-site emergency response team and local emergency personnel responded immediately and all parties are cooperating in the investigation into the cause of the incident, Singleton said.

The company has reported the incident to the Occupational Safety and Health Administration and will cooperate with the organization, Singleton said.

"Our hearts go out to the family, friends and co-workers of the employee during this very difficult time," Singleton said.

Singleton did not release the name of the employee who died, but it marked the fourth worker death at Danville’s largest private employer in a year.

On April 12, Greg Cooper, 52, a maintenance mechanic at the plant died on the job. He had worked at Goodyear for 18 years.

On March 31, Kevin Edmonds, 54, of Penhook, died during his work shift.

And in August 2015, Jeanie Lynne Strader, 56, of Chatham, died in an accident at the plant.

Danville’s Goodyear plant also had a fatality in 2007.

=============

Cause of death released for Danville Goodyear employee

By Colter Anstaett - Reporter Published: April 15, 2016, 11:46 am Updated: April 15, 2016, 6:07 pm

DANVILLE (WSLS 10) – The Medical Examiner’s Office in Roanoke has released the cause of death for the man who died earlier this week at the Goodyear plant in Danville.

He died as a result of drowning and thermal injuries. Greg Cooper died while working at the plant Tuesday morning and is the second person to die on the job in two weeks.

The Goodyear plant in Danville opened on Friday for the first time after the death. As the investigation into what happened continues, United Steelworkers, the union that represents the workers at the plant, wants some answers.

USW Director of Health, Safety & Environment Michael Wright said it is standard for them to assist the plant and OSHA in the investigation.

Wright said given that three people have died there in the last eight months, union representatives will be extra thorough with their investigation and plan to talk with representatives from the plant and Goodyear.

“When we understand the root causes, we would talk to the company through a negotiating process and say ‘these are things that need to be addressed’ and we would hopefully work with them to do that,” said Wright.

The plant voluntarily closed on Tuesday after Cooper’s death in order to conduct a thorough investigation of the incident.

Goodyear says that at the start of each shift, plant associates participated in a two-hour safety meeting where they were given the opportunity to ask questions and share any comments they may have.

Counselors will also continue to be provided on-site throughout the week, according to Goodyear.

=====================

Goodyear, USW continue investigation of death at plant

By Mike McNulty Follow Author

A Goodyear worker inspects truck tires at the plant in Danville, Va.

DANVILLE, Va.—At least three investigations into the death of a worker, the second in two weeks and the third in eight months, are being conducted at the Danville tire production plant.

Goodyear and the United Steelworkers union are conducting one probe while the Virginia Occupational Safety and Health agency and local police officials are conducting their own investigations.

The latest death occurred on April 12 when Greg Cooper, who had worked at the factory for 18 years, died from burns and drowning, according to the office of the chief medical examiner in Roanoke, Va.

A maintenance mechanic, Cooper was 52 years old, a company spokeswoman said.

In a prepared statement issued shortly after the latest accident, Goodyear said the plant's “on-site emergency response team, as well as local emergency personnel responded immediately, and all parties are cooperating in the investigation into the root cause of the incident.”

It said the company “is taking this matter very seriously” and reported the death to OSHA, which in turn launched its inspection of the facility.

Goodyear response

Goodyear temporarily closed the Danville plant to complete a full evaluation of the factory and thoroughly investigate the incident, it said. The shutdown occurred April 12, and the plant reopened on April 15.

“Our hearts go out to the family, friends and co-workers of the employee during this very difficult time,” the company said.

In a second statement, plant Manufacturing Director Greg Kerr said the company's “immediate priority is to provide support and assistance to Greg's family, as well as the entire team of associates in the Danville plant as we cope with the loss of a teammate.”

On the day the factory resumed normal operations, Goodyear issued another statement in which it noted that the investigations are ongoing.

“As associates return to their jobs,” the tire maker said in the statement, “the plant team will be keeping the safety and well-being of our associates as the highest priority.

“At the start of each shift, plant associates participated in a two-hour safety meeting where they were given the opportunity to ask questions and share any comments they may have.”

Goodyear also continued to provide counselors onsite throughout the following week.

The Goodyear spokeswoman said the company will not provide further comment on the active investigations or the first accident at the factory in August 2015.

Mike Wright, director of health, safety and environment for the United Steelworkers, said the union was conducting a joint investigation with the tire maker into what caused the latest fatality and the accident that led to the death of another plant employee—54-year-old Kevin Edmonds—March 31 in an industrial accident.

An autopsy revealed that the cause of Edmonds death was asphyxiation.

The USW sent an investigator to the Danville plant immediately after it learned about the accident, he said.

“We look at root causes and other contributing factors,” Wright said. OSHA, on the other hand, is primarily looking at violations of standards.

“There are lots of issues that must be reviewed,” he said, adding that he could not supply further specifics about the probe at this point. The investigation, while not complete, will be thorough, he added. He did not have a timetable on when he thought the probe would be complete.

Continuous inspection

Jennifer L. Rose, Virginia Occupational Safety and Health safety compliance director with the Virginia Department of Labor and Industry, said after VOSH was notified of the death at the Danville factory, it too initiated another inspection at the facility.

The agency was already in the midst of conducting an inspection of the plant following the March 31 death of Edmonds. That investigation has not been closed.

“I cannot comment on the status of any open inspections, such as this one,” Rose said. Once the investigation has been closed, VOSH will post any citations issued on the federal Occupational Safety and Health Administration web page.

She said the agency has up to six months from the opening of the inspection to issue any citations.

On Aug. 31, 2015, the Danville facility suffered the first of the three deaths when 56-year-old Jeanie Strader, a 15-year veteran of the company, was killed after being caught in machine rollers, according to an OSHA document. She was employed at Goodyear as a windup operator and roll changer.

Goodyear recently was fined $16,975 by OSHA for three serious violations at the Danville factory following an inspection after Strader's death.

UPDATE: Shelter in Place lifted in Adams Co.

By Dave Marcheskie Published: August 13, 2016, 6:43 pm Updated: August 13, 2016, 7:07 pm

NEW OXFORD, Pa — (WHTM) Emergency Alert System has lifted the ‘Shelter in Place’ alert for parts of Adam County. ABC27 is working to gather more information about the reported leak.

PREVIOUS:

Emergency Alert System has notified people in Oxford Township, Adams County of a possible ammonia leak at Plainville Farms.Officials are urging people to stay indoors and travelers to steer clear of the area.

At 6:29 p.m., EAS sent a message from the PA Emergency Management Agency telling motorists and pedestrians to avoid travel in the vicinity of New Oxford. Authorities are investigating a possible ammonia leak at Plainville Farms. People are also told to stay indoors one mile north in Hamilton Borough and Oxford Township.

Authorities said to remain indoors, close all outside and windows and turn off all ex

ternal air intakes.

===================

Pioneers in Turkey

Experts in farming since 1835, Plainville Farms was one of the first turkey companies in the country to humanely grow healthy and great-tasting turkeys with natural, time-tested methods refined over six generations of farming. Originating in the rolling hills of Central New York, the company’s reputation for growing turkeys humanely and free of antibiotics raised the bar for others in the industry. Plainville Farms’ growing methods drew the attention not only of natural food stores and major retailers, but the attention of a growing demographic of consumers who became more concerned about where their food comes from and how the animals are treated.

Experts in farming since 1835, Plainville Farms was one of the first turkey companies in the country to humanely grow healthy and great-tasting turkeys with natural, time-tested methods refined over six generations of farming. Originating in the rolling hills of Central New York, the company’s reputation for growing turkeys humanely and free of antibiotics raised the bar for others in the industry. Plainville Farms’ growing methods drew the attention not only of natural food stores and major retailers, but the attention of a growing demographic of consumers who became more concerned about where their food comes from and how the animals are treated.

Just like in 1835, our turkeys still have plenty of room to roam (although a bit less drafty than those early days). And their food is plainly vegetarian with plenty of well water. Notice we’ve said nothing about antibiotics. That’s because there are no antibiotics in our turkey. We’re proud to be old fashioned in that regard.

Of course, life moves faster than it did six generations ago. That means almost everyone can use a little help speeding dinner to the table. (As long as fast doesn’t shortcut flavor.) Fortunately, every convenient product we offer starts with the same pure, natural, Plainville Farms turkey. So whether you’re making a quick sandwich, throwing a patty on the grill or sautéing a cutlet, the result is flavor that would delight our grandparents—but at a speed that would astound them.

Engine Malfunction Causes Collision Between Boats In Boston Harbor August 13, 2016 2:19 PM

The Regency suffered minor damage in a Boston Harbor collision. (Karyn Regal/WBZ)

BOSTON (CBS) – A Boston Harbor Cruises boat lost power and rammed into several boats Saturday morning while docking at Long Wharf.

The Regency’s captain was unable to disengage from forward propulsion on the outboard starboard engine as he approached Long Wharf. The problem was caused by a malfunction in one of the boat’s four engines.

As a result, the Regency collided with two other boats, Rookie and Aurora.

Witnesses said the Regency was coming in too fast. Myron, who sells T-shirts nearby, said he saw the whole thing.

“The rear of the Regency ended up scratching the rear of the Codzilla, and then the side of the Regency ended up making contact with the docked MBTA water taxi that’s bound for Charlestown,” Myron told WBZ NewsRadio 1030’s Karyn Regal.

No one was injured, but some minor damage was reported.

The Coast Guard will inspect all three boats before returning them to service.

“We sincerely apologize to all those aboard for this situation,” Boston Harbor Cruises said in a statement. “BHC will work closely with investigators from the USCG in the coming days to complete the formal investigation.”

=====================================

Coast Guard responds to allision at Long Wharf, Boston

Aug 13th, 2016

BOSTON — A Coast Guard investigating officer and a marine inspector are responded to an allision Saturday afternoon involving three Boston Harbor cruise ships.

BOSTON — A Coast Guard investigating officer and a marine inspector are responded to an allision Saturday afternoon involving three Boston Harbor cruise ships.

No injuries or pollution have been reported.

At approximately 10:20 a.m. the Coast Guard was notified that the Boston Harbor Cruises ship Regency had allided with two other Boston Harbor Cruises Ships, the Rookie and Aurora at the pier.

Regency was returning to Long Wharf with passengers when it reportedly suffered a mechanical failure and drifted into the two other ships.

Rookie and Aurora had no passengers aboard at the time and did not appear to be damaged.

Regency reported minor damage above the waterline.

A Coast Guard investigating officer investigating the cause and a Coast Guard marine inspector will inspect all three ships prior to them returning to service.

Milan Man Killed In Logging Accident

Posted On August 11, 2016

By Mike Perleberg

Update published at 4:18 p.m.:

Rich Solano, corporate treasurer at Pike Lumber Company’s Akron, Indiana corporate headquarters made the following statement:

“Josh was a valued employee. He’s been with the company for just over nine years. He was a great guy and a very loving husband and father”.

Original story published at 11:46 a.m.:

(Ripley County, Ind.) – A lumberjack died in a tree-cutting accident in Ripley County.

Employees of Pike Lumber were working at a location along the 2100 block of State Road 229 east of Napoleon Wednesday morning, according to the Ripley County Sheriff’s Office.

Josh W. Beam, of Milan, was cutting a tree alone when a large limb fell and struck him. Two other employees nearby located him and called 911.

Beam, 33, died despite the efforts of his co-workers and first responders to resuscitate him at the scene.

According to his Facebook page, Beam had just started working this month as a timber cutter at Pike Lumber. Management at the company’s Milan operation was not prepared to comment Thursday morning, but indicated a statement regarding the employee’s death could be forthcoming.

The investigation into the logging accident is ongoing by the Ripley County Sheriff’s Office and the Ripley County Coroner. Other responding agencies included Ripley County Paramedic, Batesville Fire and Rescue, and the Napoleon Fire Department.

A construction worker was killed Friday at Fort Meade after being hit by a dump truck

A construction worker at Fort Meade died after being hit by a dump truck Friday, installation officials said.

The worker has not been publicly identified.

"The Fort Meade community's thoughts and prayers are with those affected by this loss of life, and we send our heartfelt condolences," said Col. Tom S. Rickard, the base's commander.

No further details were immediately available.

Construction on Fort Meade

Jan 27, 2016

Construction Hotline

301-677-7600

(A recorded message with the latest in construction detours and road closures.)

www.ftmeade.army.mil/pages/brac/brac_main.html

(See Fort Meade construction map for locations of specific facilities)

Change, Growth, Transformation

Fort Meade and the surrounding areas are in the midst of significant change, growth and transformation.

Fort Meade is home to 118 partner units, many of which are expanding their presence on Fort Meade. The U.S. Cyber Command, the National Security Agency and the U.S. Army Intelligence and Security Command are slated to build new facilities on the installation.

With the addition of thousands of new employees, residents and family members, Fort Meade has been busy keeping pace with necessary upgrades to its infrastructure. Miles of fiber-optic cable have already been laid to improve communication. The installation has also privatized a majority of it’s water, sewer and utility services.

The most recent construction projects completed or underway include a new AAFES Express and Post Exchange, Veterans Administration Center, transit lodging facility (Candlewood Suites), two child development centers, additional training barracks, a U.S. Army Asymmetric Warfare Group Brigade Complex and a new Rockenbach access control point, scheduled for completion in 2016. Roadway upgrades are a high priority for the garrison. Planned upgrades include improving access control points, intersections and widening main roads to four lanes. Resurfacing roads and parking lots is ongoing based on available funds.

Despite the rapid growth and transformation on the installation, Fort Meade will continue to provide world-class service to a host of tenant organizations, partner units, personnel and families.

“Key Construction Projects Support Fort Meade Growth”

Construction and facility improvements are occurring across Fort Meade. Renovation of Hale Hall and training barracks is continuing and construction on the former golf course to accommodate Cyber Command and the National Security Agency is well underway. Other construction projects are being considered by Fort Meade master planners in collaboration with our partner units.

Upgrades to Temporary Housing

In fact, construction on a brand new 243-room hotel, Candlewood Suites, near the McGlachlin Parade Field, is nearly completed. The hotel is scheduled to open in December 2015. Hotel guests can look forward to amenities such as complimentary breakfasts, weekly social activities and courtesy shuttles for on-post transportation.

Since 2009, the Army has been phasing control of its temporary lodging from the military to the InterContinental Hotels Group or IHG. Scott Myers, chief of Business Operations Division at the Directorate of Family and Morale, Welfare and Recreation, said the new hotel will provide higher-quality lodging on the installation. “Upgrading the facilities is the primary reason. We want to give our military members and families the kind of world-class facilities they deserve,” he said. IHG officially took over management control of Fort Meade’s temporary lodging facilities in May 2013.

Cyber mission expands on Fort Meade

Construction is continuing on Fort Meade’s Cyber Campus and the future home of the U.S. Cyber Command, Marine Cyber and a new NSA data center. Eventual plans include 5.8 million square feet of development, with the first phase, 1.8 million square feet, expected to be completed in 2015.

Facilities Offer Value and Variety

Elsewhere, The Army and Air Force Exchange completed construction on a new Express facility near Fort Meade’s Route 32 gate. The 8,420-square-foot Express, near the Defense Information School, features six gas pumps and an Arby’s restaurant. A donut shop is also planned.

The new 167,000-square-foot Post Exchange will features a pharmacy and a larger food court with six food vendors, including Starbucks, Domino’s Pizza, Charley’s Grilled Subs and Subway.

“It is exciting to get brand new facilities,” said Rita Inchaurregui-Powell, store manager of the Exchange and acting general manager of the Fort Meade facilities. “We’ve been in this building for so many years and it’s been pieced together, so going into a brand new building and to be able to offer new fixtures and the new department-store look -- it’s really exciting to us.”

Supporting Families and the Fort Meade Mission

Fort Meade is also expanding its child care facilities to accommodate the needs of growing families. Currently, there are three Child Development Centers on the installation to care for the dependents of service members and civilians.

Two CDC facilities are under construction to accommodate the often demanding schedule of working parents. This in turn, ensures Fort Meade’s operational mission can continue. Officials broke ground on the construction site in April 2014.

==================

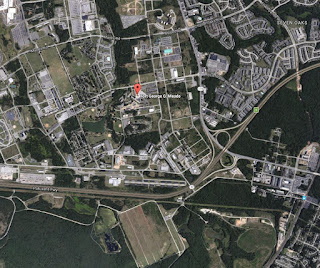

Fort George G. Meade

Is military base in Maryland

It is a census controlled defense post and it is located in Anne Arundel County in the city of Odenton in Maryland. The population of the post is little above 10,000 and it is home to National Security Agency. The project started in 1917 as one of sixteen temporarily headquarter of Army installments, where US soldiers stayed before being deployed in Europe during World War I. The site comprise of large buildings with high level security around the site. The site was named after George Gordon Meade who was a civil engineer and an officer during number of US wars including Mexican-American and American civil war.

Fort George G. Meade Facts

Location: Odenton, Anne Arundel County, Maryland

Website:

Visit Fort George G. Meade Website ›

Phone: (301) 677-6261

Longitude:

-76.719404

Latitude:

39.090394

DSN:

622-6261

Today Maryland Fort Meade is home to number of national security organizations including US Army Intelligence, US Environment Protection Agency Center, Defense Courier Security, Defense Information School and more. The post covers an area of 5000 acres and there are around 10,000 personnel working on the site, which also includes 25.000 civilians working for defense and security agency. Infact it is also home to 6000 people who live here.

The base is packed with all the facilities of a small city but having offices and headquarters to some of the most high profile agencies and organizations. The site has all the facilities for Army families living in Maryland Fort Meade. The base also have small and large communities, which works for Army families to provide comfort facilities recreational activities, they also arranges seasonal and yearly festivals that are widely attended by people. The base is divided into work group assigned different tasks such as Family Advocacy Program, Volunteer Programs, Employment Program and more.

Talking about houses on the site the housing agency works with house construction companies and designers to design and construct houses with different features, which are build as per military tradition.

Experts in farming since 1835,

Experts in farming since 1835,

BOSTON — A Coast Guard investigating officer and a marine inspector are responded to an allision Saturday afternoon involving three Boston Harbor cruise ships.

BOSTON — A Coast Guard investigating officer and a marine inspector are responded to an allision Saturday afternoon involving three Boston Harbor cruise ships.