By Connor Sheets | csheets@al.com

November 02, 2016 at 6:03 PM

Officials identified Heflin resident Anthony Lee Willingham as the worker who died in the explosion on a Shelby County gasoline pipeline. (Photo via Facebook)Connor Sheets | csheets@al.com

Officials identified Heflin resident Anthony Lee Willingham as the worker who died in the explosion on a Shelby County gasoline pipeline. (Photo via Facebook)Connor Sheets | csheets@al.com

Officials have identified the man who was killed while working on a gasoline pipeline that exploded Monday in Shelby County, Alabama.

"We can confirm the decedent is [48-year-old] Anthony Lee Willingham," Shelby County Deputy Coroner Lina Evans said via email Wednesday afternoon.

The Heflin resident was the lone member of a nine-person crew that was present at the scene of the explosion, which state officials and Colonial Pipeline – the company that owns the line – have said was instigated by a piece of excavation equipment striking the pipeline.

Little about the 48-year-old pipeline worker has been made public, and a call to his wife, Beverly Willingham, went unanswered Wednesday. The couple was married for more than 25 years and had two daughters and multiple grandchildren.

One of Anthony Willingham's daughters told WSFA Wednesday that her father was a welder and heavy machinery worker for L.E. Bell Construction of Heflin for more than two decades.

Including, Willingham, eight of the nine workers who were at the work site in Shelby County where the Monday explosion happened were employed by L.E. Bell, and one was employed by another company, Colonial told AL.com Tuesday. Four other workers who were injured in the blast were transported Monday to UAB's burn unit for treatment. Willingham's body was recovered from the blast site Tuesday morning.

David York, a spokesman for Colonial, said Tuesday that the needs of the workers who were present at the explosion site and of their family members were the company's highest priority in the initial aftermath of the blast.

"Our focus right now is the care and comfort of the injured and the family of the gentleman who died in this event," he said. "It a devastating event, not only for the company, but also for those families, and we've got to jointly get through that."

An account has been established at Metro Bank for anyone interested in

assisting the L.E. Bell families affected by the recent tragedy. Checks

and Money orders should be maid payable

to Pipeliner's Wives and can be mailed to: Metro Bank, PO Box 337,

Heflin Al 36264! We want to say a special Thank You to everyone that

has already responded. There are no words to express how much we truly

appreciate all the support, thoughts and prayers that we have received.

Here some promotional information on the L.E. Bell Construction company:

L.E. Bell Construction Co. Inc.

There are more than 2.5 million miles of natural gas and crude oil pipelines in the United States, making it the largest such network in the world, according to the American Petroleum Institute.

“Pipelines exist almost everywhere – natural gas is delivered directly to homes in relatively small-diameter distribution lines buried under the street and even your own yard,” the institute says. “Larger cross-country transmission pipelines delivering gasoline, home heating oil, or moving crude oil or natural gas are actually easier to find.”

Pipelines can range in length from one mile to more than 1,000 miles, as well as vary in diameter. The approximately 55,000 miles of crude oil transmission lines in the U.S. that connect regional markets typically range from eight to 24 inches in diameter. Oil gathering lines, located primarily in oil-producing states such as Texas and North Dakota, are significantly smaller, ranging from two to eight inches in diameter.

The natural gas pipeline network in the United States is a highly integrated network of both transmission and distribution lines. This network can transport natural gas to and from any location in the continental United States and includes more than 210 natural gas pipeline systems totaling more than 305,000 miles of interstate and intrastate transmission pipelines, the institute adds.

Project Partnerships

L.E. Bell Construction has played a role in making sure natural gas and oil reach their destinations for more than 40 years. Founded in 1974, the Heflin, Ala.-based contractor provides pipeline construction services to the municipal, utility and heavy construction markets. The company is led by owner and President Larry Bell and his son Mike Bell, senior vice president. “We do our best to do the job right the first time,” the company says.

L.E. Bell Construction performs projects both as a primary contractor as well as in conjunction with a number of subcontractors. These include contractors with whom it has worked for several years.

One company L.E. Bell has regularly worked with is REM Directional, a Boligee, Ala.-based directional drilling company. REM Directional has worked on several projects in collaboration with L.E. Bell since 2006. “With every job we’ve done they’ve supported us very well, and we’ve done a good job helping them complete their projects,” REM Directional President Joel Colgrove notes. “L.E. Bell is probably one of the best contractors out there today.”

One notable project involving both companies was in 2012, when REM Directional completed the drilling for a 9,500-foot natural gas pipeline in Jackson, Miss., for Gulf South Pipeline Company, LP. The installation was completed in one continuous shot, with REM Directional needing to take 11 90-minute stops to allow L.E. Bell to weld sections of pipe together before resuming the job.

Headquartered in Houston, Gulf South is an interstate natural gas pipeline system that “gathers gas from basins between Texas and Alabama and delivers it to on-system markets within its footprint and to off-system markets in the Northeast, Midwest and Southeast through interconnections with third-party pipelines,” it says. Gulf South is located in the Gulf Coast states of Texas, Louisiana, Mississippi, Alabama and Florida. The company also owns and operates salt dome and reservoir natural gas storage facilities in Mississippi and Louisiana.

L.E. Bell has also worked extensively with Delta Directional, a directional drilling company headquartered in Newton, Miss. “Since our inception in 2001, Delta Directional Drilling has proven that we have the experience to complete any bore,” the company says. “With more than 100 years of combined knowledge in the horizontal directional drilling industry, we can take on even the most challenging of crossings.”

Delta Directional’s projects with L.E. Bell are performed with the company’s core values of “experience, integrity and perseverance” in mind. “We believe in doing the best job for our clients in a timely, cost-efficient manner. We have built strong relationships with our clients by ensuring jobs go as smoothly as possible,” Delta Directional says. “Our proven track record allows them to rest assured that they are getting a top-quality horizontal directional drilling contractor.”

Delta Directional operates 18 drilling rigs that give it the ability to work in marsh, clay, sand, gravel, cobble and rock formations. The company has completed crossings with pipe sizes ranging from 2 to 48 feet in rock formations exceeding 57,000 psi. “Every crossing has its own unique set of challenges,” the company says. “We believe that any obstacle can be overcome with proper planning and hard work. This has allowed us to persevere.”

Supplier Services

L.E. Bell and its subcontractors complete their projects using materials from several key suppliers including Snapper Industrial Products. The Atlanta-based company offers pipe, valves, fittings, tools, equipment and installation services to L.E. Bell and its other customers. Snapper Industrial Products is a distributor for a number of brands including Apollo, American Valve, Crane, Milwaukee Value, Homestead, Shurjoint and Nibco.

“We pride ourselves in our service and personal relationship with our customers,” Snapper Industrial Products says. “Our complete inventory services every piping and industrial need, from the smallest job to the largest.”

Other important suppliers include National Trench Safety. “Whether your crews are working in the trenches or between the barricades, their success and yours is linked directly to the partners you choose,” the Houston-headquartered company says. “That’s why thousands of contractors, municipalities and developers rely on us for trench boxes, trench shields, slide rail systems, message boards, barrier walls and more.”

National Trench Safety operates a national network of branch locations, which gives it the ability to respond quickly to customer needs. This includes providing on-site technical expertise and on-time equipment delivery. “We also offer trench and traffic safety training to keep your crews OSHA-compliant and safe on the jobsite,” the company says.

High Standards

L.E. Bell Construction performs all of its projects with the highest safety standards in mind. The company in recent years had its safety program and policies completely revised by United Safety LLC during a five-month audit.

Founded in 1994, United Safety LLC provides auditing, consulting and training services to clients in several fields including industrial, oilfield, petrochemical, refining, pipeline, residential, mining, commercial construction, insurance, legal and specialty contracting.

“Through these years our team has successfully guided its clients through the ever-developing world of employee safety, health and security,” the company says. “Proof of this success is evident by the long-term relationships we have built with our clients, many of whom have been with us since our inception 20 years ago, solidifying the importance and value of our service to their companies and employees alike.”

San Francisco sues developer over sinking tower

Published November 03, 2016

Associated Press

In this photo taken Monday, Sept. 26, 2016, is the Millennium Tower in San Francisco. (AP Photo/Eric Risberg)

SAN FRANCISCO, CA – San Francisco on Thursday filed a lawsuit against the developers of a sinking and tilting luxury high-rise, claiming they knew about the problems but did not disclose the information to potential home buyers as required by law.

Millennium Tower was completed about eight years ago and so far has sunk 16 inches into the soft soil and landfill of the city's crowded Financial District. The sinking has been uneven, creating a 2-inch tilt at the base and a roughly 6-inch lean at the top.

City Attorney Dennis Herrera filed the suit against Mission Street Developers LLC as a cross-complaint of a previous lawsuit filed by homeowners against the Transbay Joint Powers Authority. The authority is building the new Transbay Transit Center next door.

"We are not going to sit by and allow a developer— or anyone else — to enrich themselves at the expense of others by hiding crucial information that they're required by law to disclose," Herrera said at a news conference Thursday. "That gave the developer an unfair advantage against competitors, and it cheated homebuyers out of information they needed to make an informed decision."

Herrera said an investigation showed that the developer knew by February 2009, before any condos were sold, that six inches was the maximum amount of settlement predicted for the 58-story tower by the projects geotechnical engineer. However, by the time the sleek, mirrored high-rise was completed around February 2008, it had already settled by almost six inches.

"Buyer beware doesn't cut it here," he said.

When the Millennium Tower opened, it became a haven for the well-heeled, and all 419 apartments quickly sold out. Tenants have included former San Francisco 49er Joe Montana, late venture capitalist Tom Perkins and Giants outfielder Hunter Pence.

The building has a sprawling indoor lap-pool, a health club and spa, an in-house cinema, and a restaurant and wine bar run by celebrity chef Michael Mina. Penthouses have sold for more than $10 million.

The developers said the allegations by the city attorney have no merit. Spokesman PJ Johnston said developers complied with all state and local laws regarding disclosure to potential buyers.

Johnston said the joint powers authority's dewatering of the underlying soils, and excavation and construction have caused the tower to settle beyond the 12 inches that were predicted.

"It is unfortunate that Mr. Herrera, who is also legal counsel for (the authority), has chosen to take the focus off finding a fix for the building and is instead attempting to divert attention from the real culprit here — a government agency that has behaved recklessly, caused damage to a previously existing building, and still refuses to take any of the steps that are necessary to fix the problem," Johnston said in an email.

EPA Enforcement Actions Help Protect Vulnerable Communities from Lead-Based Paint Health Hazards

11/03/2016

Contact Information:

Tricia Lynn (lynn.tricia@epa.gov)

(202) 425-3623

WASHINGTON – The U.S. Environmental Protection Agency (EPA) today announced over 100 federal enforcement actions completed over the last year that require entities like renovation contractors, landlords and property managers to protect communities and public health from exposure to lead. Lead paint is the main way people are exposed to lead in the United States, and lead exposure can cause a range of health problems, from behavioral disorders and learning disabilities to seizures and death, putting young children and their developing nervous systems at the greatest risk.

“Renovation companies and their contractors must protect children and other vulnerable people from lead-based paint exposure, especially in minority and low-income communities where housing with lead-based paint is more common,” said Cynthia Giles, assistant administrator for EPA’s Office of Enforcement and Compliance Assurance. “These enforcement actions show that EPA will hold companies accountable when they put public health at risk, and they promote a level playing field for businesses that follow the rules.”

From October 2015 through September 2016, EPA entered into 123 settlements for alleged violations of one or more of the three lead-based paint rules--the Renovation, Repair and Painting (RRP) Rule; the Lead Disclosure Rule; and the Lead-based Paint Activities Rule for abatements--and filed six complaints for ongoing actions. Each settlement requires that the alleged violator return to compliance and, in most cases, pay civil penalties. Collectively, the settlements require violators to pay $1,046,655 in penalties.

The three rules are part of the federal Toxic Substances Control Act and the Residential Lead-Based Paint Hazard Reduction Act and apply to housing built before 1978 and child-occupied facilities. Ensuring compliance with all three rules enables EPA to identify and address a variety of lead exposure risks that occur in communities across the nation. These risks can occur when lead paint deteriorates or is disrupted during home renovation and remodeling activities. A blood lead test is the only way to determine if a child has a high lead level. Parents who think their child has been in contact with lead dust should contact their child's health care provider.

In September 2016, EPA and the U.S. Department of Justice announced a settlement with Sears Home Improvement Products Inc. that resolves alleged violations of the Lead RRP Rule for work performed by Sears’ contractors during home renovation projects across the country. Under the settlement, Sears will implement a comprehensive, corporate-wide program to ensure that the contractors it hires to perform work minimize lead dust from home renovation activities and pay a $400,000 civil penalty.

In three of the settlements, entities agreed to fund voluntary environmental projects collectively valued at up to $409,429 to address lead risks and poisoning. Every project requires lead-based paint abatement, including post-construction clearance testing to ensure that no hazards remain. The complaints propose penalties of up to $197,743 for alleged violations of the RRP Rule and/or Lead Disclosure Rule.

Renovation, Repair and Painting (RRP) Rule Enforcement Action

Of the total settlements reported during fiscal year 2016, 116 cited alleged RRP Rule violations involving repair, renovation or painting projects where lead-based paint is disturbed. Approximately 63 percent of this year’s cases alleged failure to obtain EPA certification and almost half cited non-compliance with requirements to ensure lead-safe work practices.

The following are highlights from settlements involving significant penalties and/or supplemental environmental projects:

Hammer and Hand, Inc., located in Oregon, paid a $69,398 penalty for alleged RRP Rule work practice and recordkeeping violations.

Clearview Home Improvements, located in California, paid a $58,450 fine for alleged noncompliance with RRP Rule requirements for certification, pre-renovation education, firm responsibility, and recordkeeping.

Zidan Management Group, Inc., located in Indiana, agreed to perform an abatement project valued at up to $41,500 and paid a $3,675 fine to settle alleged violation of RRP Rule work practice and certification requirements. The RRP Rule requires that individuals performing renovations are properly trained and certified, give owners and occupants EPA’s Renovate Right lead hazard information pamphlet before beginning work and follow specific lead-safe work practices during renovations.

Lead Disclosure Rule Enforcement Actions

Five of the settlements reported in fiscal year 2016 alleged Lead Disclosure Rule violations. This rule continues to be an important tool for reducing lead exposures and increasing awareness of lead risks. The rule generally requires lessors and sellers to disclose to prospective tenants and purchasers specific information about lead-based paint and lead-based paint hazards.

In one case, a landlord in Illinois, committed to perform a $308,000 lead abatement project and pay a $5,000 cash penalty to settle alleged Lead Disclosure Rule infractions. This case was a joint enforcement action by EPA and the U.S. Department of Housing and Urban Development, prosecuted by the U.S. Department of Justice.

In another case, Carrington Real Estate Services, LLC and Carrington Mortgage Services, LLC, both in California, agreed to spend at least $59,929 to donate blood-lead test equipment to non-profit community health clinics, and pay a $19,976 penalty to settle alleged Lead Disclosure Rule infractions.

Lead-based Paint Activities Rule - Abatement Enforcement Actions

The Lead-based Paint Activities Rule requires that abatement contractors be trained and certified, and follow abatement-specific lead-safe work practices. EPA-authorized states typically implement and enforce the abatement requirements of this rule. However, during fiscal year 2016, EPA took action in two cases. In one case, Lead Me Out Environmental Services, Inc. of New York paid a civil penalty of $20,000 for alleged abatement violations.

More information about all of EPA’s actions to enforce lead-based paint regulations during fiscal year 2016 is available at https://www.epa.gov/enforcement/fy2016-enforcement-actions-lead-renovation-repair-and-painting-rule-rrp.

More information about the lead-based paint regulations and hiring a certified renovation company is available at www.epa.gov/lead or by calling the National Lead Information Center at 1 (800) 424-LEAD.

EPA settles with WestRock CP for $4.6 million to reimburse cleanup costs at former wood treating plant

11/03/2016

Contact Information:

Margot Perez-Sullivan (perezsullivan.margot@epa.gov)

415-947-4149

SAN FRANCISCO, CA – The U.S. Environmental Protection Agency has settled with WestRock CP, LLC, which will pay $1.6 million in cash plus shares of stock valued at nearly $3 million as partial reimbursement for a hazardous waste cleanup near Prescott, Ariz.

The site is a former wood treating plant located on the Yavapai-Prescott Indian Tribe reservation, and cleaned up by the EPA using its authority under the Comprehensive Environmental Response, Compensation and Liability Act (the Superfund law). In 2012, EPA discovered significant amounts of arsenic and pentachlorophenol-contaminated material at the abandoned site. The Agency spent $6.1 million removing 4,209 tons of contaminated soil during a two-month-long cleanup.

“This unique settlement was structured to allow the Agency to receive corporate shares instead of a full cash payment,” said Enrique Manzanilla, Director of the Superfund Program for the EPA’s Pacific Southwest Office. “We are pleased to recover the majority of the taxpayer-provided funds spent on the environmental cleanup on tribal lands.”

The shares of stock being transferred to the Agency include 56,064 shares in WestRock CP, LLC’s parent company, WestRock Company, and 9,344 shares of a newly established spin-off company, Ingevity Corporation. The EPA will sell the stock once the settlement is finalized in federal District Court. The combined stock current value is $2,998,406.

Southwest Forest Industries Inc. operated the wood treating plant from 1961-1985, and a successor company, Smurfit-Stone Container Enterprises, Inc. went bankrupt, leaving the cleanup obligations with the current corporate successor, Westrock, CP LLC, a manufacturer of paperboard and paper-based packaging.

Pentachlorophenol, an industrial wood preservative, is extremely toxic and can cause neurological, blood, and liver effects, and eye irritation in the short term and long term impacts on the respiratory tract, blood, kidney, liver, immune system, eyes, nose, and skin. Arsenic, used to formulate a common wood preservative, can cause gastrointestinal effects, anemia, peripheral neuropathy, skin lesions, hyperpigmentation, and liver or kidney damage in humans.

The consent decree is subject to a 30-day public comment period. To view the consent decree or to submit comments, please visit: https://www.justice.gov/enrd/consent-decree/us-v-westrock-cp-llc

Jury gets death case against LI excavation company’s foreman

Updated November 2, 2016 9:04 PM

By John Riley john.riley@newsday.com

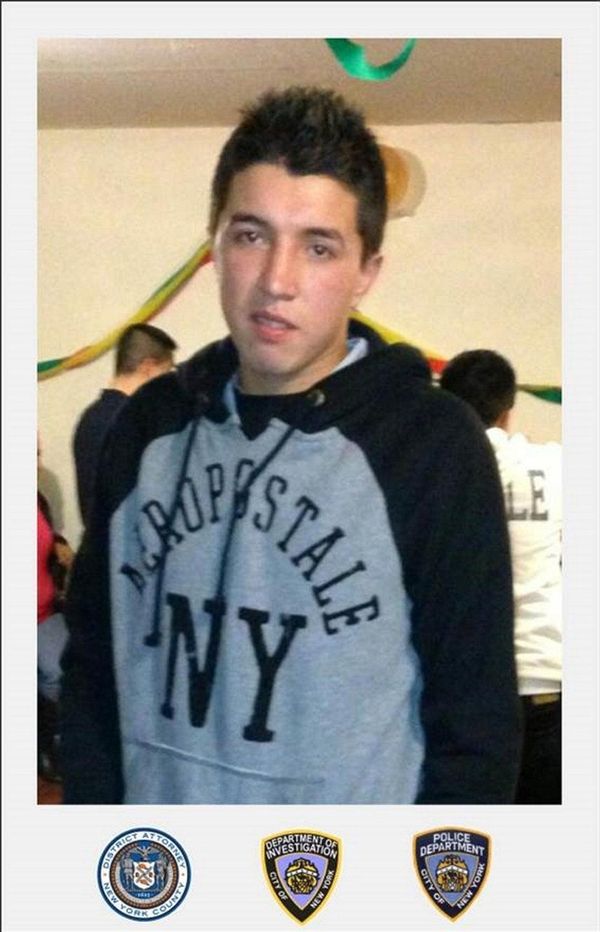

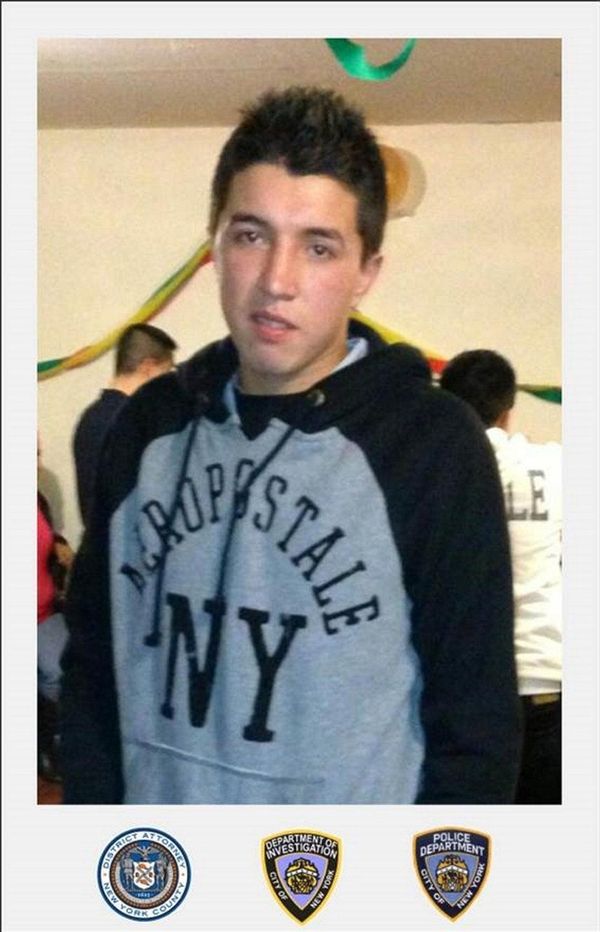

Carlos Moncayo, 22, an illegal Ecuadorean worker crushed in a trench collapse in New York City on April 6, 2015, is seen in an undated file photo. Photo Credit: Manhattan District Attorney

The Long Island excavation company foreman charged in the cave-in death of illegal immigrant worker Carlos Moncayo last year was too untrained on risks and safety procedures to be held criminally responsible, his lawyer argued Wednesday in summations at his Manhattan manslaughter trial.

Cesar deCastro, the lawyer for foreman Wilmer Cueva, told jurors that Cueva’s employer, excavation subcontractor Sky Materials Corp. of Calverton and Queens, and the general contractor were responsible for the collapse of an unshored 14-foot trench that killed Moncayo.

“Sky Materials sent their untrained workers into a dangerous job site without the basic knowledge necessary to safely perform the work,” said deCastro, who also questioned the authenticity of a federal Occupational Safety and Health Administration training card issued in Cueva’s name.

Moncayo, 22, an undocumented Ecuadorian, died April 6, 2015, on a West Side site being readied for Restoration Hardware. General contractor Harco Construction LLC has already been convicted of manslaughter, and a jury deadlocked on charges against Harco site supervisor Alfonso Prestia. A retrial is expected.

Sky also is charged and has not yet been tried, but instead of blaming the company, prosecutor Diana Florence cited testimony that Cueva warned laborers to be careful when sending them into the deep trench as proof that he knew the risks and ignored them to quickly prepare for a concrete delivery.

Start of Sky foreman Wilmer Cueva's trial in the cave-in death case. Ninth Avenue on the day of April 6, 2015, for recklessly causing the death of Carlos Moncayo, a SKY employee, by failing to heed and address repeated warnings about unsafe work conditions at an active construction site. Mr. Moncayo was killed when an unsecured trench in which he was working collapsed and fatally crushed him. The defendants are charged in New York State Supreme Court indictments with Manslaughter in the Second Degree, Criminally Negligent Homicide, and Reckless Endangerment in the Second Degree. Photo Credit: NYPD

Start of Sky foreman Wilmer Cueva's trial in the cave-in death case. Ninth Avenue on the day of April 6, 2015, for recklessly causing the death of Carlos Moncayo, a SKY employee, by failing to heed and address repeated warnings about unsafe work conditions at an active construction site. Mr. Moncayo was killed when an unsecured trench in which he was working collapsed and fatally crushed him. The defendants are charged in New York State Supreme Court indictments with Manslaughter in the Second Degree, Criminally Negligent Homicide, and Reckless Endangerment in the Second Degree. Photo Credit: NYPD

“He told the workers to be careful and work quickly because the sides could fall . . . as if they could defy gravity by sheer will and speed,” she said.

Cueva, 51, of Elmwood Park, New Jersey, is charged with reckless endangerment and criminally negligent homicide in addition to manslaughter, which requires proof that he recklessly disregarded deadly risks.

DeCastro described Cueva as a “laborer with a title,” a Spanish-speaker without the English skills to fully grasp things he was told, who wasn’t trained enough to know the risks, while Florence has portrayed Cueva as a “knowledgeable” manager who ignored warnings from inspectors.

One dispute at trial focused on testimony from an OSHA manager that agency records indicated Cueva and a number of other Sky employees — including owner Michael Cholowsky — attended an OSHA safety course through a Staten Island trainer, and received OSHA cards certifying the training.

Cueva never testified, but deCastro challenged the authenticity of the training.

Among other glitches, he said, the records listed two addresses for the training company — one nonexistent, one a parking lot and cheesesteak shack on Staten Island — as well as misspelling Cueva’s name and providing a ZIP code for the “Sky Masters” training location that didn’t match the address.

“This is the type of evidence the prosecution wants you to rely on,” he told jurors.

But Florence insisted Cueva’s card had been validly issued, and described the issue as a red herring.

“The trench that Wilmer created violated plain common sense,” she said. “And this danger is not something you need to take an OSHA class to learn about.”

Lawyers for Sky and Cholowsky, 52, of Manhasset, did not respond to emails seeking comment. The jury began deliberations, and is expected to resume on Thursday.

Officials identified Heflin resident Anthony Lee Willingham as the worker who died in the explosion on a Shelby County gasoline pipeline. (Photo via Facebook)Connor Sheets | csheets@al.com

Officials identified Heflin resident Anthony Lee Willingham as the worker who died in the explosion on a Shelby County gasoline pipeline. (Photo via Facebook)Connor Sheets | csheets@al.com

Start of Sky foreman Wilmer Cueva's trial in the cave-in death case. Ninth Avenue on the day of April 6, 2015, for recklessly causing the death of Carlos Moncayo, a SKY employee, by failing to heed and address repeated warnings about unsafe work conditions at an active construction site. Mr. Moncayo was killed when an unsecured trench in which he was working collapsed and fatally crushed him. The defendants are charged in New York State Supreme Court indictments with Manslaughter in the Second Degree, Criminally Negligent Homicide, and Reckless Endangerment in the Second Degree. Photo Credit: NYPD

Start of Sky foreman Wilmer Cueva's trial in the cave-in death case. Ninth Avenue on the day of April 6, 2015, for recklessly causing the death of Carlos Moncayo, a SKY employee, by failing to heed and address repeated warnings about unsafe work conditions at an active construction site. Mr. Moncayo was killed when an unsecured trench in which he was working collapsed and fatally crushed him. The defendants are charged in New York State Supreme Court indictments with Manslaughter in the Second Degree, Criminally Negligent Homicide, and Reckless Endangerment in the Second Degree. Photo Credit: NYPD