REDUCING MUSCULOSKELETAL DISORDERS AMONG AIRPORT BAGGAGE SCREENERS AND HANDLERS

Summary

Baggage screeners and handlers at airports are exposed to manual baggage lifting and handling that are associated with work-related musculoskeletal disorders (WMSDs). The National Institute for Occupational Safety and Health (NIOSH) evaluated two mechanical lift aids to determine if they could reduce the risk of WMSDs. The two mechanical lift aids reduced some physical WMSD risk factors such as hand loading and spinal compression force.

Description of the Problem

Approximately 45,000 baggage screeners and 173,700 baggage handlers are employed in U.S. airports by the Transportation Security Administration (TSA) and airline carriers, respectively. Manual lifting and materials handling have been shown as main risk factors for WMSDs [NIOSH 1997]. The average weight of checked bags is about 32 lbs, and the maximum baggage weight can reach up to 70 lbs or more [NIOSH 2014]. Manual baggage lifting and handling are therefore considered the main risk factors for WMSDs among bag- gage screeners and handlers. A portion of the checked bags are manually handled by baggage screeners, while every checked bag is required to be manually transferred to airplanes by carrier bag- gage handlers.

In most airports, checked bags are screened by screening machines. If ma- chine screening cannot be completed, manual screening is required to clear bags in a baggage screening area. To perform manual screening tasks, a bag is typically lifted or pulled by a baggage screener from the inbound conveyor. Once manual screening is completed, the bags are lifted to an outbound conveyor that is separate from the inbound conveyor, requiring lifting and carrying. If screening machines are located in the airport lobby area, baggage screeners may be required to manually lift each checked bag twice—transporting the bag from the floor to the machine and from the machine to the conveyor connected to the baggage make-up area for airline carriers. Therefore, baggage screeners working in checked baggage screening areas may be involved in intensive baggage lifting in some set- tings, particularly during rush hours.

Once checked bags are cleared by baggage screeners, they typically are transported on a conveyor to the bag- gage make-up area where the checked bags are manually transported to bag- gage carts and then airplanes by carrier baggage handlers. Carrier bag- gage handlers who work in the ramp area (i.e., the area where airplanes are parked for departure and arrival) lift bags onto a belt loader from a cart, handle bags at the airplane cargo compartment doors, and stack bags inside cargo compartments. They reverse the operations when bags are unloaded from the cargo compartments. Carrier baggage handlers typically lift 5−10 bags per minute during loading/ unloading to the airplane [Oxley et al. 2009]. Risk factors for WMSDs associated with these tasks include heavy lifting, awkward and restricted postures (in the small cargo areas), and time pressure [Tapley and Riley 2005; Ta- pley et al. 2007]. The problem is more acute when handlers load narrow- bodied airplanes with a cargo ceiling ranging from 46−55 inches. Auto- matic container systems for loading and unloading checked baggage have been used in larger airplanes, but are not available for narrow-bodied airplanes.

NIOSH Case Studies

NIOSH evaluated the effect of two ergonomic interventions on the risk of WMSDs among baggage screeners [NIOSH, 2014]. The main findings are summarized below:

Vacuum Lifting Assist Device

Operation of the vacuum lifting assist system (Figure 1) involves pushing and pulling the controller as the vacuum power lifts the bag. Three bag weights (25, 40, and 50 lbs) were tested in the study. When the system was used, the average minimal pushing/pulling force was reduced to 2.7, 4.0, and 4.2 lbs, respectively. Compared to the hand forces measured during lifting, this was approximately a 90% reduction when using the vacuum system. In addition, the vacuum lifting assist system resulted in improved postures (near neutral trunk flexion angles) because of the adjustable controller that can keep the bag at the optimal height for lifting. The reduced hand force and improved posture resulted in a 63% measured reduction of the compressive force in the lower back [NIOSH 2014].

Figure 1. A baggage handler lifts a bag with a vacuum lifting assist device

Automatic Baggage Moving System

The automatic baggage moving system (Figure 2) is a conveyor that helps move the bags from the screening area to the outbound conveyor. Unlike the traditional conveyor systems, this system does not connect the two ends of the working area. It connects to one end at a time, then moves itself automatically to the other end as it senses the bag that is loaded to the moving system. This system might be shared between two work stations connected by a roller bed. This intervention eliminates lifting entirely, but requires manual pushing to load the bag from the screening table through the roller bed to the baggage moving system.

Figure 2. An automatic baggage moving system

The average pushing force is about 80% of the force required for manual lifting of a 25- or 50-lb bag. The posture and force involved in using the system resulted in a 44% reduction in the compressive force in the lower back [NIOSH 2014].

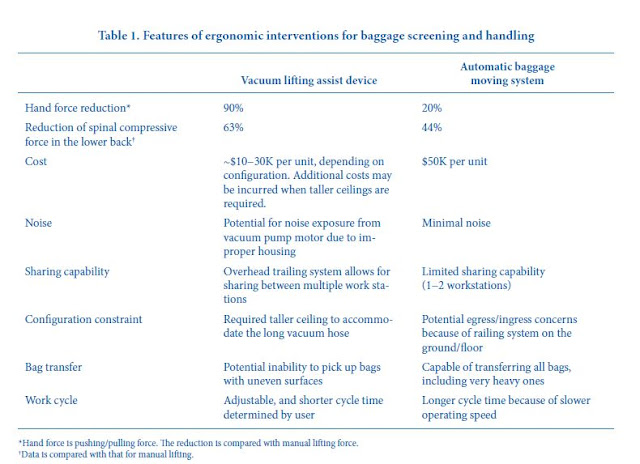

Table 1 summarizes the features of the vacuum lifting assist and the automatic baggage moving systems.

Other Risk Control Methods

Mechanical lift aids are recommended to be used as the primary risk reduction method for baggage handling [Tapley and Riley 2005; Tapley et al. 2007]. For baggage handling in the airplane cargo space, certain methods of loading and stacking bags may also help reduce strain on the back [Vatan- Korkmaz et al. 2006]. These may include marking heavy bags so they can be slid into the cargo and lighter bags lifted on top [Vatan-Korkmaz et al. 2006]. Job rotation, short breaks, and training on proper lifting procedures (lifting above the knees, below the shoulder, and close to the body) are other administrative controls that may help reduce the risk of injury [Dell 1998; NIOSH et al. 2007]. Baggage-handling jobs are associated with low levels of employee control over tasks, time pressure, and low social support [Rosskam 2007]. These workplace factors may also play a role in the development of WMSDs, although they are not as evident as the physical job demands [NIOSH 1997; da Costa 2010]. Reductions in the workplace stressors in the work environment may help prevent WMSDs [Hauke et al. 2011].

Acknowledgments

This document was prepared by Ming-Lun Lu, Susan Afanuh, Robert Dick, Dwight Werren, and Thomas Waters of the National Institute for Occupational Safety and Health. The authors would like to thank Brian Lowe, Tarah Cole, Jessica Burkhart, and the TSA for their support in data collection and analysis. Mention of any company or product does not constitute endorsement by NIOSH.

References

BLS [2011]. Incidence rates for nonfatal occupational inju- ries and illnesses involving days away from work per 10,000 full-time workers by occupation and selected events or ex- posures leading to injury or illness, private industry, 2010. Washington, DC: US Bureau of Labor Statistics, Table R100. http://www.bls.gov/iif/oshwc/osh/case/ostb2924.pdf

Da Costa B, Vieira E [2010]. Risk factors for work-related musculoskeletal disorders: A systematic review of recent logitudinal Studies. American J Ind Med 53:285–323.

Dell G [1998]. Airline baggage handler back injuries: a sur- vey of airline baggage handlers opinion on causes and prevention. Safety Science Monitor 2(2):2−12.

Hauke A, Flintrop J, Brun E, Rugulies R [2011]. The impact of work-related psychosocial stressors on the onset of musculoskeletal disorders in specific body regions: A review and meta-analysis of 54 longitudinal studies. Work and Stress 25(3):243–256.

NIOSH [1997]. Musculoskeletal disorders and workplace factors, a critical review of epidemiologic evidence for work-related musculoskeletal disorders of the neck, upper

extremity and low back. By Bernard B. Cincinnati, OH: US Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Oc- cupational Safety and Health. http://www.cdc.gov/niosh/ docs/97-141/

NIOSH, CAL OSHA, CNA, E.A.S.E., DIR [2007]. Ergonomic guidelines for manual material handling. DHHS (NIOSH) Publication No. 2007−131. http://www.cdc.gov/ niosh/docs/2007-131/pdfs/2007-131.pdf

NIOSH [2014]. Bag handling assist controls for airport screening processes. By Lu M, Dick R, Werren D, Lowe B. NIOSH Publication No. EPHB-010-22a.

Oxley L, Riley D, Tapley S [2009]. Musculoskeletal ill-health risks for airport baggage handlers. London: Health and Safe- ty Executive. http://www.hse.gov.uk/research/rrpdf/rr675.pdf Rosskam E [2007]. Excess baggage. Leveling the load and changing the workplace. Amityville, NY: Baywood Publishing Company Inc.

Tapley S, Riley D [2005]. Baggage handling in narrow- bodied aircraft: identification and assessment of musculo- skeletal injury risk factors. London: Health and Safety Executive. http://www.hse.gov.uk/airtransport/docs/baggage.pdf

Tapley S, Riley D, Oxley L [2007]. Baggage handling in narrow-bodied aircraft: further risk identification. London: Health and Safety Executive. http://www.crcnetbase.com/ doi/abs/10.1201/9780203883259.ch74

Vatan-Korkmaz S, et al. [2006]. Baggage handling in an airplane cargo hold: an ergonomic intervention study. Int J Ind Ergonomics 36:301−312. http://biodynamics.osu.edu/publication%20pdf/2006/Baggage%20Korkmaz%202006.pdf

Suggested Citation

NIOSH [2015]. Reducing musculoskeletal disorders among airport baggage screeners and handlers. By Lu M, Afanuh S, Dick R, Werren D, Waters T. Cincinnati, OH: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health. DHHS (NIOSH) Publication No. 2015-201