Hydrogen Sulfide (H2S) Gas Release from Piping Corrosion Failure Near a Weld at an oil platform

Hydrogen sulfide corrosion has been plaguing the oil and gas industry for many decades. Unless this issue is addressed in areas where high concentrations of hydrogen sulfide are expected or have been measured, catastrophic failures have and will continue to occur.

The Incident

The location of the H2S release was on Platform Hidalgo on

Lease OCS-P 0450. This is offshore the

California coats. It occurred on

February 23, 2012.

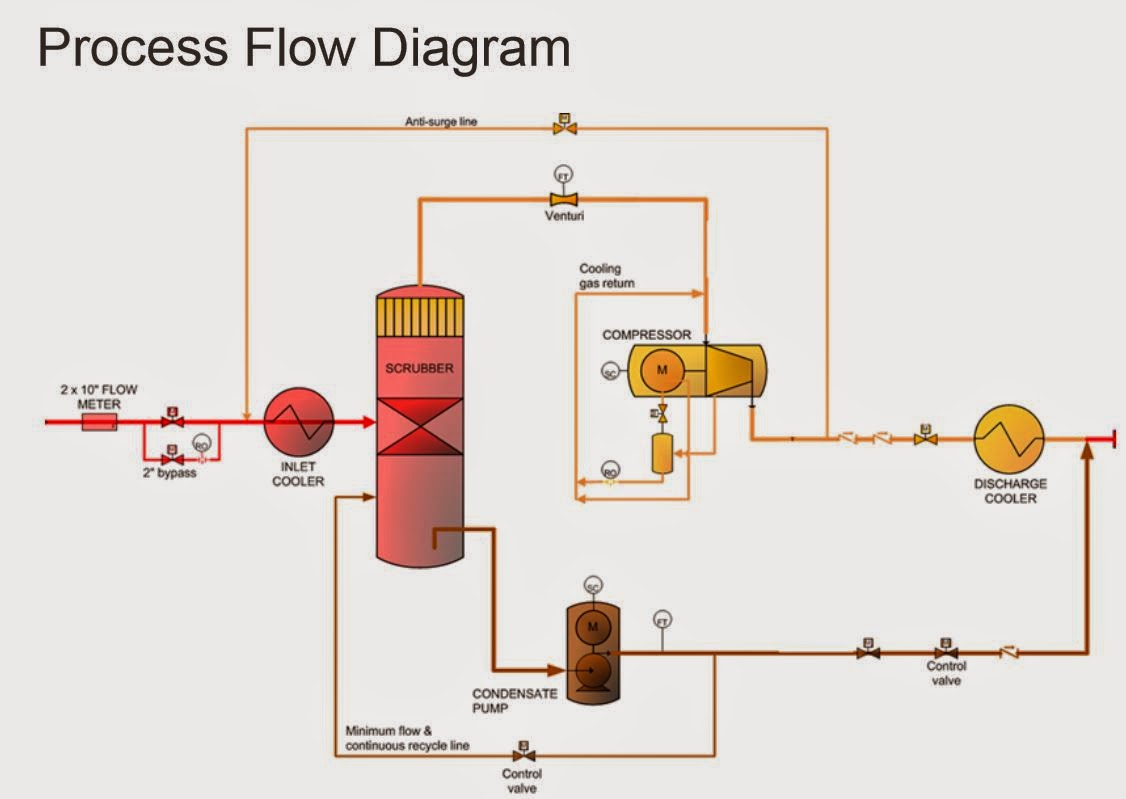

A hydrogen sulfide

(H2S) gas release

occurred from a piping corrosion failure

near a weld, on the 8-inch side of an 8-inch by 4-inch reducer on the blowdown

line for a third-stage section compression scrubber. Multiple H2S sensors detected

the release and initiated

a platform shutdown. Platform personnel were directed to muster to the safe briefing areas.

Response personnel using breathing apparatus isolated the leak. No injuries

to any personnel occurred from the incident.

Prior to the platform

being restarted, the failed spool was removed

and saved for testing, and a new spool was installed. The H2S concentration at the release point was estimated to be 40,000 ppm.

Investigation

An incident investigation revealed the following:

The cause of the H2S release was a weld failure

on the side of the reducer.

This failure was caused

by accelerated corrosion resulting from elemental

sulfur in contact

with steel in an area where deposits

could build up. Elemental

sulfur acts as an oxidizer

and is known to accelerate steel corrosion

and cause localized reduction in wall thickness. The elemental

sulfur in the scale was the result

of oxygen contamination in the wet, sour gas stream. Oxygen reacts

with hydrogen sulfide

in liquid water to form elemental sulfur.

Contributing factors to the accelerated corrosion include:

high H2S concentrations sufficient

to introduce elemental

sulfur which exacerbates the corrosion process

and low flow rate in the area of the failure due to the reducer configuration. The areas in the reducer with higher flow rates did not have heavy buildup

of corrosion products.

The reducer spool that failed

is included in a piping

circuit in the operator’s Mechanical Integrity Program.

The circuit was last examined

in May 2011 utilizing a non-destructive test (NDT) ultrasonic “A” scan that was run at specific points on the circuit. The results of the 2011 inspection did not indicate any issues that required corrective action.

NDT results for the piping

circuit covering the last 10 years showed no appreciable loss in wall material thickness.

The ultrasonic inspection procedures used to examine the piping circuit

may not have been effective in identifying the potential

for a weld failure because

the procedures were designed to assess the pipe’s thickness and were taken on a smooth surface

at some distance away from the weld’s location. In addition, the voluminous scale deposits on the steel

surface may have affected the accuracy of the

inspection results.

On August 3, 1999, at

about 2:00 p.m., an 8-inch high pressure gas flowline

on Platform Hermosa ruptured,

resulting in a sour gas release. The break occurred on the mezzanine

deck, about 64 feet above the ocean,

downstream of a third-stage discharge

scrubber, V-14, and just prior to the glycol contactor inlet, V-16. The drop in

pressure activated the automatic safety system on the platform, which shut in oil

and gas production. Platform Hidalgo, with pipelines transporting oil and gas to Platform

Hermosa, was also shut in.

The released gas had an

H2S concentration of about 18,000 ppm. The H2S alarms

on Platform Hermosa activated. No

one on Platform Hermosa was harmed. No harm

to seabirds or other wildlife was observed.

The flowline failed due to

internal corrosion, which reduced

the wall thickness until it could

no longer contain the normal operating pressure. Corrosion was caused

by

condensed liquid water reacting with H2S

gas to form a corrosive acid gas.

Recommendations

Therefore, we recommend

that operators:

·

Inspect all piping

with similar internal exposure, i.e., wet, sour gas where

water and deposits

can accumulate, and replace if

extensive corrosion is identified.

·

Review inspection and

maintenance programs for piping exposed

to sour gas and

·

include procedures for identifying localized corrosion problems using radiography or other

non-destructive inspection methods where normal ultrasonic inspection may not be

effective, such as the areas near welds,

reducers, and flanges.

Verify that your Safety and Environmental

Management System program adequately addresses the design, inspection, testing and quality assurance of piping exposed to

sour gas in order to prevent the buildup of

elemental sulfur and to identify and remediate

areas of excessive corrosion so that similar releases of H2S gas

can be prevented.

Safety Alerts can be found

on the following BSEE webpage: http://www.bsee.gov/Regulations-and-Guidance/Safety-Alerts/Safety-Alerts/

Panel Investigation Reports can be found on the following BSEE webpage: http://www.bsee.gov/Inspection-and-Enforcement/Accidents-and-Incidents/Panel-Investigation-Reports/Panel-Investigation-Reports/

Metropolitan Engineering, Consulting &

Forensics (MECF)

Providing Competent, Expert

and Objective Investigative Engineering and Consulting Services

P.O. Box 520

Tenafly, NJ 07670-0520

Tel.: (973) 897-8162

Fax: (973) 810-0440

E-mail: metroforensics@gmail.com

We are happy to announce the launch of our twitter

account. Please make sure to follow us at @MetropForensics or @metroforensics

Metropolitan appreciates

your business.

Feel free to recommend our

services to your friends and colleagues.