A paper worker was killed and four others were sent to the emergency room for treatment when an overheated air compressor ignited oil vapors inside the compressor and air receiver tank.

Prior to the explosion and resulting warehouse fire, a paper machine and supporting equipment were shut down to replace a leaking 3-inch ‘mill’ water line valve.

The shut down of the well water pump caused a decrease in water flow to the air compressors. (There were five, rotary screw, 400 horsepower Gardner Denver Electra-Saver Stationary Base Mounted Compressors with two 16’ tall and 7’ in diameter 7,500-gallon receiver air tanks, manufactured by Wheeler Tank Manufacturing Company and two chiller units located above the compressors.)

These compressors were changed from air-cooled to water-cooled approximately two years before the accident.

Prior to the accident, three of the five compressors were in operation. Two of them tripped out due to high temperatures; one continued to run.

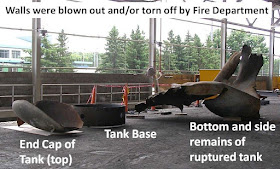

When the operating compressor’s internal temperature exceeded 300-degrees Fahrenheit, it caught on fire. Within seconds, the receiver tank catastrophically ruptured due to an explosion of oil vapors inside of the tank. (The flash point of the oil is 210-degrees Fahrenheit).

The explosion and fire damage was so severe and extensive that the paper mill has been shut down permanently with the loss of 259 jobs.

Recommendations to Prevent Recurrence:

- Make certain that thermal protection shut down devices are operational and cause a default shut down of the equipment in accordance with the manufactur-er’s instructions and specifications.

- Maintain proper cooling water supply (flow rates) required by the manufacturer.

- Ensure proper care, use and maintenance of the compressor and supporting equipment on a maintenance log per the manufacturer’s directions.

- Compressor control screens need to have alarms for high oil temperatures.

- Conduct a Management of Change before modifying equipment, operating practices and Comprehensive Job Safety Analysis before non-routine maintenance.

- Develop, document and utilize effective hazardous energy control procedures (Lockout/Tagout/Verify) for the control of potentially hazardous energy when maintenance and service work is being performed on equipment.

- Provide effective education/training to employees (including non-routine tasks).