OSHA Rules on Anhydrous Still Debated

BY DTN/Progressive Farmer | March 25, 2016

Robert Kylio/iStock/Thinkstock

OMAHA (DTN) — As John Oehlerking was busy applying anhydrous ammonia Tuesday on his farm near Elmwood, Nebraska, he had more on his mind than the usual precautions and care typically given the fertilizer. Oehlerking wondered if he would even have access to the popular, and low-cost, nitrogen fertilizer in the future.

If the Occupational Safety and Health Administration (OSHA) succeeds in changing the rules governing the storage and handling of anhydrous, some fertilizer retailers have said they’ll stop carrying it.

“While this would affect fertilizer retailers first, it also would also have a huge negative effect on farmers and Main Street,” Oehlerking told DTN.

Historically, agricultural retailers had an exemption to OSHA’s Process Safety Management of Highly Hazardous Chemicals (PSM) regulations, which governed storage and handling rules around products such as anhydrous ammonia. The PSM was written with large-scale anhydrous manufacturing and distribution facilities in mind. Those facilities, which store many times the amount of anhydrous gas a retailer has on hand during the application season, have strict storage and safety requirements such as a high level of storage security, specific tank testing and replacement requirements, specific signage, and a higher level of worker safety training.

The retailer exemption from PSM rules is expected to end on Oct. 1. Originally, in a July 2015 announcement that it would end the PSM exemption, OSHA said retailers would fall under full rules at the end of that year.

On Dec. 18, buried in the 2016 Omnibus Appropriations Act, was a rider that forbid OSHA from requiring fertilizer retailers to comply with PSM regulations. The rider further required that OSHA conduct a formal rule-making process, complete with public comment period, before any change could be implemented.

OSHA PRESSES ON

OSHA officials responded that the specifics of the exemption meant the agency did not have to follow Congressional dictates.

“The courts have said we can make interpretations without going through the full regulatory process,” Jordan Barab, OSHA deputy assistant secretary, told DTN. “This is not regulatory change but an interpretation change.”

The agency plans to begin PSM enforcement activities Oct. 1, at the start of the 2016-17 government fiscal year.

Rocky Weber, president and general counsel of the Nebraska Cooperative Council, took a delegation of state ag retailers to Washington D.C. the week of March 14 to visit Nebraska’s senators and representatives about the PSM exemption.

“What we are pushing for is statutory requirements in the Appropriations Bill or some other legislation that extends the date of enforcement and requires OSHA to take more time with this,” Weber said. “We don’t think OSHA has thought about the unintended consequences.”

With Congress in the beginning stages of marking up the 2017 appropriations bill, Weber said his group is seeking one or more legislators in each house add language to stop the enforcement of the PSM standard against fertilizer retailers until OSHA undertakes formal rule making and allows greater public input.

Nebraska Sen. Deb Fischer introduced an amendment to the Energy Modernization Act this winter that included several stipulations for OSHA before submitting the final rule on the removal of the retail exemption from the PSM standard. Cloture on this bill was invoked before Sen. Fischer’s amendment could be heard.

HIGH INDUSTRY COSTS

Weber points out his organization fully supports the safe handling of anhydrous and also understands it is OSHA who makes these regulations. The unintended consequences of this change could cost millions of dollars to fertilizer retailers and ultimately farmers.

OSHA estimated that the cost to retailer would be fairly small, roughly $2,100 per location. In a report on the issue, The Agricultural Retailers Association put those estimates in excess of $20,000 per site.

Retailers have told DTN the costs, including the cost of engineering plans to alter existing storage facilities, would be near $77,000. At those cost levels, retailers have said, they’d likely stop handling anhydrous ammonia, and push farmers to alternative, and more expensive, nitrogen fertilizers.

“The removal of this exemption has the potential to take significant dollars out of farmers’ pockets,” Oehlerking, the Nebraska farmer, said.

Oehlerking is on the board of directors of Midwest Farmers Cooperative in Elmwood and also sits on the board for the Nebraska Cooperative Council. He is concerned about retailers deciding they can’t afford the costs associated with these new OSHA regulations with smaller independent retailers and even some cooperatives may decide to stop selling anhydrous completely.

The Nebraska Cooperative Council surveyed some of their Nebraska cooperatives members. Four cooperatives out the 32 located in the state estimated approximately $40 million in costs. It is a foregone conclusion that nationally the cost to the agricultural industry of removing the retail exemption from PSM standard application far exceeds $100 million, he said.

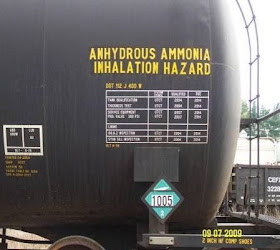

Weber said that one example of application of the PSM standard would be that all anhydrous tanks have a legible data plate. Tanks without this plate would have to be replaced and replacement costs for one tank would cost approximately $110,000. Most retailers have several of these tanks that would need replacing.

“In addition, it would take six months to get one tank and that does not even meet their deadline this fall,” Weber said.

Barab said the need for data tags, “essentially birth certificates,” is an existing requirement under EPA and other OSHA requirements dealing anhydrous, and is a requirement under many local laws. “It does not have anything to do with the changes in PSM.”

“I think there are a lot of misinterpretations about what is going on with these PSM changes,” Barab said. “Most of the elements of the PSM are already required for these employers and these additional requirements should not add any more burdens.”

UNINTENDED COSTS

Oehlerking and Weber said there are many indirect costs that will happen if retailers stop carrying anhydrous.

“I just bought an anhydrous applicator a year and half ago and I worry about the value of that machine if anhydrous sales are discontinued if these change occur,” Oehlerking said. “There is part of me who wants to sell it now before it has no value.”

There could be major logistic issues if anhydrous is not in the farmers’ tool box of fertilizers, he said.

His local co-op handles 30,000 tons of anhydrous annually, and estimates it will take 60,000 tons of dry fertilizer to replace that anhydrous. This would require roughly 6,000 rail cars annually to deliver product to Midwest.

Replacing the anhydrous with UAN liquid would require the coop to purchase, store and deliver another 75,000 tons of liquid fertilizer, which would require 7,500 rail cars annually. Oehlerking noted it would also require 2 to 3 times more truck traffic to move dry or UAN products to farmers on an already stressed road and infrastructure system.

A shift away from anhydrous could have major implications for farmers even if they don’t use anhydrous in their operation.

“With one less N source, some estimated nitrogen prices would increase anywhere from $30 to $50/acre for farmers,” he said.

Oehlerking said he believes OSHA needs to go through the formal rule changing process and also needs to slow down and not begin enforcing their changes this year. He understands the need for safety regulations and does not want to circumvent safety rules but he would like to see OSHA take years not months to implement these changes.

“The best option would be if they just continue to exempt fertilizer retailers like they have for 20-plus years, this would solve a lot of our issues,” Oehlerking said.

“This is an issue that will negatively impact the financial well-being of all farmers in an already struggling ag environment,” he said.

==========

What is the Process Safety Management Standard?

To help prevent unexpected releases of toxic, reactive, or flammable liquids and gases in processes involving highly hazardous chemicals, OSHA has issued the Process Safety Management of Highly Hazardous Chemicals standard (29 CFR 1910.119), which contains requirements for the management of hazards associated with processes using highly hazardous chemicals. Regardless of the industry that uses these highly hazardous chemicals, there is a potential for an accidental release any time they are not properly controlled, creating the possibility of disaster.

Process safety management (PSM) is addressed in specific standards for the general and construction industries. OSHA's standard emphasizes the management of hazards associated with highly hazardous chemicals and establishes a comprehensive management program that integrates technologies, procedures, and management practices.

What is the Retail Exemption and what will the revised guidance do?

The PSM standard exempts retail establishments, but does not define what a retail establishment is. The preamble to the standard explained that the exemption was adopted because hazardous chemicals would be present in these facilities only in small volume packages, containers and allotments, and therefore retail facilities would not present the same degree of risk of a catastrophic release as other workplaces.

It listed gasoline stations as one example of such a facility. The previous interpretations of the retail facility exemption were inconsistent with both the standard’s protective purpose, and the explanation provided in the preamble, and removed facilities like West Fertilizer from OSHA oversight under the PSM standard. The new interpretation will make the definition of a retail establishment consistent with the intent described in the preamble to the final PSM rule and to match the common definition of retail establishment used by the Department of Commerce.

Why will OSHA modify its retail exemption?

The President, in Executive Order 13650, directed OSHA to identify any changes that need to be made to the retail exemption in order to enhance safety and security in chemical facilities. The action that OSHA is taking is intended to improve the safety and security for American workers and neighboring communities, allowing for inspections of processes involving highly hazardous chemicals at facilities and helping to prevent incidents like the West Fertilizer explosion.. OSHA will modify its interpretation of the retail exemption to be consistent with the intent described in the preamble to the final PSM rule and to match the common definition of retail establishment used by the Department of Commerce. The previous interpretation exempted facilities like West from the requirement of the PSM standard and prevented OSHA from performing regular oversight.

How does the interpretation relate to Executive Order 13650 and the incident at West Fertilizer?

The President issued Executive Order 13650 shortly after the incident at West Fertilizer in order to improve chemical facility safety and security. Agencies involved in the execution of the order examined all regulatory and policy gaps that allowed West Fertilizer, and other facilities storing, manufacturing, or handling large inventories of hazardous chemicals, to operate without sufficient and effective oversight. OSHA found policy and regulatory gaps, specifically that the previous interpretation of retail facility prevented OSHA from routinely overseeing or inspecting highly hazardous sites, such as West.

The previous interpretation for example, prevented OSHA from including facilities like West in national or local emphasis programs such as OSHA’s Chemical Facilities National Emphasis Program. Fixing the gaps clarifies regulatory coverage for facilities and helps OSHA better reduce hazards at facilities holding large inventories of hazardous chemicals in a more targeted way.

When does the new interpretation of the retail exemption take effect?

As with any OSHA interpretation, it takes effect immediately. However, because the new interpretation changes long-standing policy on this issue, for the first six months after this announcement, OSHA plans to use its enforcement discretion when inspecting facilities formerly covered by the old policy and will generally not cite those facilities during this period to give them time to come into compliance.

The only exception to this policy will be if OSHA discovers conditions at such a facility that expose workers to an immediate and severe danger, and OSHA determines that the employer has not made a reasonable good faith effort to eliminate or substantially control the hazard. In this rare circumstance, the agency may consider enforcement action to address the immediate and severe danger. Any enforcement action in this situation must be approved by OSHA’s National Office.

Furthermore, if compliance officers find PSM hazards at establishments inspected during the delay period, the employer will be referred to OSHA’s compliance assistance and consultation teams for assistance with those specific hazards. Compliance officers may direct employers to (online compliance guidance (http://www.osha.gov/SLTC/processsafetymanagement/index.html) or third parties such as the Agricultural Retailers Association (www.aradc.org) who have developed compliance tools.

How will the upcoming modification to OSHA’s PSM retail facility interpretation affect employers?

Employers with covered processes are already effectively complying with most of OSHA’s PSM requirements through requirements of EPA’s Risk Management Program (RMP) rule (40 CFR 68)1, known as RMP Program 2. Therefore, employers would have to review their current process safety management systems to ensure that they meet any additional requirements of PSM. This could include some modifications to existing management system elements such as: standard operating procedures, hazard analyses, employee participation in the development and

1 http://www2.epa.gov/sites/production/files/2013-10/documents/chap-02-final.pdf

implementation of the process safety management systems, reviews prior to startup of new or modified processes, welding safety procedures, and safety implications of process or equipment changes affecting covered chemicals (Management of Change). OSHA believes the process safety information, maintenance, and emergency response elements that are already included in RMP2 would likely need no further modification by the employer to be PSM-compliant.

Additionally, the facilities covered by RMP Program 2 and OSHA’s current retail exemption interpretation policy, are mostly simple storage and handling facilities; therefore, any additional PSM program development, outside that already developed for RMP Program 2 purposes will be relatively straightforward and simple. Common examples include anhydrous ammonia (AA) or liquefied petroleum gas (LPG) dispensing. These dispensing operations comprise primarily a pressure vessel, a simple piping network, a pump, and a delivery hose. Additional actions necessary to comply with PSM in simple, pure chemical service such as AA and LPG dispensing should not cause significant new burdens for employers.

Will small employers receive help developing, initiating, and instituting my PSM program?

Yes. Each state has an OSHA funded On-site Consultation Program that offers free and confidential safety and occupational health advice to small and medium-sized businesses in all states with priority given to high-hazard worksites. These state-run on-site Consultation services are completely separate from OSHA enforcement and do not result in penalties or citations. Consultants from state agencies or universities work with employers to identify workplace hazards (including those involving highly hazardous chemicals), provide advice on compliance with OSHA standards, and assist in establishing injury and illness prevention programs.

About 98 percent of all businesses assisted by OSHA’s On-site Consultation Program have fewer than 250 employees at the worksite. Small businesses subject to the PSM standard can contact the OSHA On-site Consultation office in their state to review their current PSM systems to ensure that these businesses meet the requirements. Employers can visit the OSHA Web site (https://www.osha.gov/dcsp/smallbusiness/consult.html) to find contact information for their local On-site Consultation provider to obtain assistance.

Note also that employers using OSHA’s free consultation service available are deferred from OSHA’s programmed/scheduled inspections (i.e., those scheduled as part of National or Local Emphasis Programs) while the consultation remains “in progress.” This period encompasses the time between the onset of the consultation and the final correction dates, including any extensions. Inspections of fatalities, reported injuries, and complaints are not deferred.

Did OSHA estimate the economic impact of the policy changes?

OSHA estimates that changing the interpretation of the retail exemption may affect up to 4,800 facilities. Because a majority of these facilities have only one covered chemical (Anhydrous Ammonia), tend to be quite small, and are already required to comply with EPA’s Risk Management Program 2 requirements[1], OSHA expects no individual businesses will be significantly adversely affected. Specifically, OSHA estimates that the initial national cost could be as low as $10.4 million (or $2,160 per facility) with ongoing annual costs a fraction of the initial costs.

The current requirements of RMP, Emergency Planning and Community Right-to-

Know Act (EPCRA), and Superfund Amendments and Reauthorization Act (SARA) Title III caused industries, including fertilizer distribution, to initiate safety management practices such as hazard analysis, training, maintenance, and emergency planning. OSHA’s Process Safety Management (PSM) standard cohesively integrates five additional elements to the already robust safety management system at these facilities: management of change, contractor management, prestart-up safety review, hot work, and employee participation. Employers would only have to review their current process safety management systems to ensure that they meet any additional requirements of PSM. This could include some modifications to existing management system elements such as standard operating procedures and hazard analyses, procedures for ensuring employee participation, procedures prior to startup of new or modified processes, welding safety procedures, and assessing the safety implications of any process or equipment changes that may be made affecting covered chemicals

Does PSM apply to non-manufacturing facilities, such as rural, agricultural-related facilities?

Yes. OSHA has consistently applied the PSM standard to non-manufacturing processes such as those at rural, agricultural-related distribution facilities. In fact, most PSM-covered processes involve a non-manufacturing application of the highly hazardous chemical (ammonia refrigeration, chlorine disinfection, chemical storage). Anhydrous ammonia storage at distributorships is no different.

Will this change in the interpretation of the retail exemption result in the closure of local facilities, the loss of jobs, higher food production costs?

No. OSHA does not believe that a change in the interpretation of the retail exemption will result in significant design changes at distributorships. See the question on economic impacts above.

Will this change mean that distributorships will be required to deliver Anhydrous Ammonia in smaller quantities?

No. Distributorships will be able to conduct business the same way they do now. They will just be required to comply with those PSM requirements that are not now required under EPA’s Risk Management Program. The size of storage vessels and shipments likely will not change. It is important to note that OSHA does not regulate shipment of anhydrous ammonia in nurse tanks nor does OSHA regulate the application of anhydrous ammonia as a soil nitrifier at farms.