June 27, 2016

On March 25, 2016, the U.S. Department of Labor, Occupational Safety and Health Administration (Fed OSHA), issued its long-awaited final rule on “Occupational Exposure to Respirable Crystalline Silica,” 29 CFR sections 1910, 1915 and 1926. The new regulations, which go into effect within the next 90 days, significantly reduce the permissible amount of silica dust that workers may be exposed to, and require employers to implement controls and practices that reduce silica exposure.

The new regulations also provide specific guidance for construction employers on what they must do to limit exposure during common construction tasks, such as use of a variety of saws, drills, jackhammers and handheld power chipping tools, machines, heavy equipment and utility vehicles. This article highlights key provisions of the new regulations to assist employers in preparing for compliance.

Who Does This Affect?

The new regulations will bring increased attention and enforcement efforts regarding silica dust exposure, particularly in the construction, maritime and hydraulic fracturing industries. All employers whose operations involve materials containing silica will need to take proactive stems to implement compliant exposure control plans, training and medical monitoring. The industries primarily affected by the new regulations include:

- Construction

- Glass Manufacturing

- Pottery Products

- Structural Clay Products

- Concrete products

- Foundries

- Dental laboratories

- Painting and coatings

- Jewelry production

- Refractory products

- Landscaping

- Ready-mix concrete

- Cut stone and stone products

- Abrasive blasting

- Refractory furnace installation and repair

- Railroads

- Hydraulic fracturing for gas and oil

- Asphalt products manufacturing

What Are the Requirements?

The standards applicable to general industry and the maritime industry require that employers:

- Measure the amount of silica that workers are exposed to if it may be at or above the“action level” of 25 micrograms per cubic meter of air, averaged over an eight hour day;

- Protect workers from exposure above the new permissible exposure limit (“PEL”) of 50 micrograms per cubic meter of air, averaged over an eight hour day;

- Limit access to areas where workers could be exposed above the PEL;

- Use dust controls such as water or ventilation to protect workers from exposure above the PEL;

- Provide respirators to workers when silica dust controls cannot limit exposure to the PEL;

- Restrict housekeeping practices that expose workers to silica dust when there are feasible alternatives;

- Establish and implement written exposure control plans that identify exposure risks and methods used to protect workers;

- Offer medical exams, including chest X-rays and lung function tests, every three years for workers exposed at or above the“action level”;

- Train workers on operations that result in exposure and ways to limit exposure; and

- Keep records of exposure and medical exams.

How Should Companies Stay Compliant?

The standards applicable to the construction industry require that employers:

- Establish and implement written exposure control plans that identify methods used to protect workers, including restriction of access to areas of high exposure;

- Designate a competent person to implement the plan;

- Restrict housekeeping practices that expose workers to silica dust when there are feasible alternatives;

- Offer medical examinations, including chest X-rays and lung function tests, every three years for workers required by the new rule to wear a respirator for 30 or more days per year;

- Train workers on operations that result in exposure and ways to limit exposure; and

- Keep records of exposure and medical exams.

The new regulations provide specific guidance for construction employers on what they must do to limit exposure during common construction tasks, such a use handheld power saws and drills. Employers who do not follow the Fed OSHA recommended control methods must measure the amount of silica dust workers are exposed to whenever the exposure may be at or above the “action level,” protect workers from silica dust exposure above the PEL, and provide respirators when dust control methods cannot limit exposure to the PEL.

What Is The Timeline?

The new regulations become effective on June 23, 2016, after which employers will have one to five years to fully comply depending on the industry. Construction employers must comply by June 23, 2017. General industry and maritime employers must comply by June 23, 2018. Employers in the hydraulic fracturing industry must comply by June 23, 2018.

Why the Change?

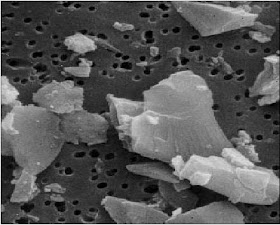

According to Fed OSHA, 2.3 million workers are exposed to respirable crystalline silica in the workplace, including 2 million construction workers who“drill, cut, crush, or grind silica-containing materials such as concrete and stone.” Excessive exposure to respirable crystalline silica has been linked to silicosis, lung cancer, other respiratory diseases, and kidney disease. Fed OSHA estimates that the new rule will save over 600 lives and prevent over 900 new cases of silicosis each year.

Regulations promulgated by California’s Department of Industrial Relations, Division of Occupational Safety and Health (“Cal OSHA”) also limit exposure to silica, as follows: respirable crystalline silica (quartz, fused, tripoli) -- 0.1 milligrams per cubic meter of air; total crystalline silica (quartz) -- 0.3 milligrams per cubic meter of air; and respirable cristobolite and tridymite -- 0.05 milligrams per cubic meter of air. Information about Cal OSHA’s silica dust exposure regulations is available at www.dir.ca.gov/dosh/etools/08-019/sources.htm.

To read more about the new Fed OSHA regulations, please visit: www.osha.gov/silica.