Cleaning Ship Emissions with Metal Sponges

By MarEx 2015-09-03 20:33:47

The world shipbuilding industry is facing drastically stricter requirements for emissions starting this year, and by 2020 emissions will need to be cut even more.

Given this outlook, many vessels are now on a desperate hunt to find new technology that will remove polluting particles from their exhaust emissions, and a pilot project developed by Norway’s NTNU researchers Carlos Dorao and Maria Fernandino shows great promise.

Their technology was originally designed for the gas industry. The production of natural gas involves complicated processes to separate the gas and liquid from each other after being extracted from a well. Separators used in the industry today are expensive and bulky.

Their technology was originally designed for the gas industry. The production of natural gas involves complicated processes to separate the gas and liquid from each other after being extracted from a well. Separators used in the industry today are expensive and bulky. Dorao and Fernandino – in collaboration with others – came up with the idea to use a steel sponge along with centrifugal force to remove the fluid from a gas stream, offering a brand new solution for the gas industry.

The hybrid solution is called the Lynx Separator. InnSep was created as a company in 2011 to further develop the researchers’ original idea and to test a more scalable and flexible version of the gas/liquid separator. CEO Sondre K. Jacobsen was hired, and the company’s local office is based at the Gløshaugen Innovation Centre in Trondheim, Norway.

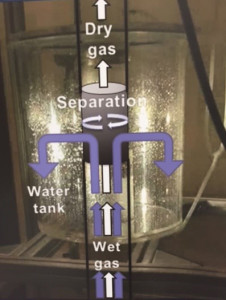

The concept is as follows: Wet gas flows through the separator. A tubular metal sponge spins rapidly, separating the liquid from the gas and throwing it to the side and down, allowing dry gas to stream up to where it’s needed.

The Research Council of Norway has now funded a pilot project to examine the possibility of applying Dorao’s and Fernandino’s separator technology to cleaning the exhaust emissions from ships.

The pilot project has tested liquid at 20-30 degrees. Since ship exhaust typically ranges from 60-70 degrees, one of the goals is to incorporate heat exchangers into the developing technology.

Next, InnSep will take the pilot project results to market players.

Source: Gemini