State teams testing and disinfecting towers for Legionnaires' disease in Bronx; 108 infecte, 10 died thus far

NEW YORK (WABC) --

The Legionnaires' outbreak likely started at one or more of the

sites where the bacteria that causes the disease was detected last week,

said Mayor Bill de Blasio Saturday.De Blasio said at a news conference Saturday afternoon that 108 people have been infected since the outbreak surfaced in July. 10 people have died.

"This is literally uncharted territory and it's important we recognize that we've never seen an outbreak of Legionnaires' like this in the history of New York City," he said. Of course we know that lack of maintenance of the cooling towers and other equipment is the main cause of the bacterial infection. No excuse, Mr. Mayor. Just clean up the water equipment and implement a regular maintenance program.

De Blasio said that one or more of the five sites announced last week where Legionnaires' had been detected, likely caused the start of the outbreak:

-- Lincoln Hospital, remediation completed

-- Concourse Plaza, remediation completed

-- Opera House Hotel, remediation completed

-- Verizon remediation, completed Streamline Plastic Co., remediation completed

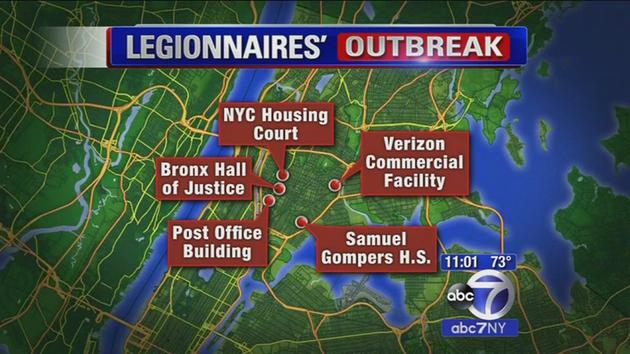

He also identified five new sites that were cleaned and disinfected after the bacteria was found:

-- 1106 Hoe Ave. (Verizon commercial facility)

-- 118 Grand Concourse (New York City housing court)

-- 245 E. 161 St. (Bronx Hall of Justice)

-- 554 Grand Concourse (Post office building about to be decommissioned turning into a commercial building this month )

-- 455 Southern Blvd.(Samuel Gompers High School)

The disease is a form of pneumonia caused by breathing in mist contaminated with the Legionella bacteria. There have been no new deaths reported over the past two days and no new cases in the last four days, de Blasio said. Seventy-six people have been treated and discharged of the 94 people who have been hospitalized in this outbreak.

"This outbreak is clearly tapering off," the mayor said, adding that emergency room visits are down in the South Bronx.

On Saturday, 57 cooling towers in New York were disinfected; all 161 buildings with possible cooling towers will have been inspected and disinfected by Sunday with 200 people working around the clock, said de Blasio.

New York state officials are deploying teams to help test cooling towers amid a deadly outbreak of Legionnaires' disease.

Gov. Andrew Cuomo said began working Saturday in the Bronx. State officials have said they'll pay for the testing.

Under Cuomo's direction, on Saturday state health commissioner Dr. Howard Zucker arrived at Montefiore Robert Moses facility to test for the bacteria. Test results will take at least a week.

"We're going to get a sample and find out what we have," Zucker said.

Hospital staff said they followed strict guidelines on keep the cooling towers. "All owners of coin towers got a notice from the New York City commissioner to sanitize their towers, so we're doing that but we have a great maintenance program where we clean the towers twice a year," said Edward Pfleging, Montefiore senior vice president of facilities.

State officials stress that they're working in conjunction with the city health department. But their presence in the Bronx comes a day after the long-simmering feud between Cuomo and de Blasio ignited again over their administrations' response to the outbreak.

There is no indication that Legionella has contaminated water systems in buildings.

By the end of this year, the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) plans to finalize Standard 188, “Prevention of Legionellosis Associated with Building Water Systems.” The standard addresses plumbing systems, cooling towers, and several other types of water systems or devices that can harbor Legionella bacteria and release water droplets into the air. As ASHRAE states, the purpose of this upcoming standard “is to present practices for the prevention of legionellosis associated with building water systems.”

The new standard won’t be the first document to discuss the risk of Legionnaires’ disease associated with cooling towers and ways to minimize that risk. Government agencies and industry associations issued guidelines years ago, including ASHRAE in 2000, and articles on Legionella have appeared in industry publications for decades. What makes ASHRAE Standard 188 different is that it requires a HACCP (Hazard Analysis and Critical Control Point) plan.

Facility managers (fms) should bear in mind that a HACCP Legionella plan involves, not just cooling towers, but plumbing systems, decorative fountains, whirlpool spas, and other water systems that can harbor and transmit Legionella.

Creating a HACCP boils down to four steps that fms need to take:

- assess the hazard;

- establish control measures and monitoring;

- verify that the control measures are implemented; and

- validate that the plan is working.

- Locate cooling towers to minimize exposure to people. Place the towers as far away as reasonably possible (preferably at least 100') from operable windows, outdoor air intakes, parking lots, roads, driveways, sidewalks, and outdoor areas frequented by people. Furthermore, make ground level cooling towers inaccessible to visitors and passers-by (e.g., with a fence or wall).

- Treat cooling water for control of Legionella and other microbes. Fms should communicate to their water treatment vendor that their treatment program should be effective against a wide range of microbes, including Legionella, in biofilms as well as in the circulating water.

- Fms should follow ASHRAE Guideline 12-2000, “Minimizing the Risk of Legionellosis Associated with Building Water Systems,” regarding cooling tower shutdown and startup.

- Check water treatment chemical levels and chemical pumps daily. Legionella levels can skyrocket in a short time if a biocide drum is empty or a chemical pump is broken.

- Install and maintain high efficiency drift eliminators. Even the most efficient drift eliminators will not block all Legionella bacteria but they will minimize the mist that escapes the tower.

- Control the buildup of dirt and debris. Clean basins and sumps as needed and the entire system twice a year. The cleaning alone has little effect on Legionella concentrations, but it is crucial for effective water treatment. Fms should also consider side stream filtration to reduce suspended solids and the demand on the biocide further. For most systems, filtering 3% to 5% of the circulated water to 20 to 50 microns is sufficient. A filter vendor can recommend a media based on a particle size analysis.

- Routinely purge stagnant lines. Stagnant water is conducive to Legionella growth and prevents the biocide from circulating throughout the system.

- Test the water routinely to evaluate the water treatment program and the overall risk reduction plan. For most cooling towers, tests for pH, total dissolved solids, and disinfectant levels (if applicable) should be run daily. Check total bacteria counts (TBC) or Adenosine Triphosphate (ATP) at least once a week to evaluate the water treatment—a significant rise indicates a problem.

Fms should also consider monitoring biofilm. Slime on any test surface indicates there’s slime in less accessible areas (e.g., heat exchangers).

Other Actions Required

In addition to control measures, the HACCP system requires the following:- Identify and train the people responsible for the cooling tower maintenance and water treatment.

- Set specific control limits (e.g., acceptable bacteria counts) and determine remedial steps to take if those limits are exceeded.

- Establish a reporting system that verifies the plan was implemented.

- Document all inspections and maintenance procedures.

//------------///

The Legionella bacterium, Legionella pneumophila

— the fundamental agent of Legionnaires’ disease — is a water-based

organism that causes infection when inhaled in aerosol form.

Legionnaires’ disease acquired its name in 1976, when an outbreak of

pneumonia occurred among attendees of a convention of the American

Legion in Philadelphia. Later, the bacterium causing the illness was

named Legionella.

Normally linked to cooling towers, evaporative condensers, mist machines, humidifiers, whirlpool spas and showers, L. pneumophila is most commonly associated with the disease outbreak (legionellosis) that is caused by the inhalation of contaminated water in the form of aerosol spray that is smaller than 5 μm. Legionella bacteria thrive in stagnating water, such as in tanks, reservoirs, dead legs in piping systems and poor-flow areas. They require temperatures between 68°F and 113°F (under 68°F, they survive, but over 140°F, they are killed) and a supply of nutrients found in algae, rust, sludge and scale.

Disease Prevention

Health agencies continually draw attention to the risks and best practices for cooling water treatment for cooling towers and evaporative condensers. Conditions that affect the proliferation of Legionella include:

Managing the risks from Legionella in water systems requires a holistic approach and a suite of control measures underpinned by a suitable and sufficient risk assessment specific to the system in question. In areas with hard water, scale formation can be a problem unless properly managed, and can increase the likelihood of Legionella growth.

The Role of Scale

Scale, or limescale, is a hard, rock-like deposit of calcium or magnesium salts that forms in heat exchangers, cooling tower packing and other water-fed equipment as a result of heat and increased concentration factor. Scale formation impairs heat transfer, interferes with flow and cooling, and can be a breeding ground for Legionella.

The scaling tendency of a water supply depends on the hardness of the water; still, if not adequately treated, even relatively soft waters can become highly scaling when concentrated by evaporation. Poor scale control not only puts the cooling process at risk, but also can squander thousands of dollars in wasted energy, chemical and water charges.

Scale is a problem in both hot- and cold-water systems. Dripping taps can deposit scale in and around the tap, and with high ambient room temperatures provide an ideal growth medium for L. pneumophila. In hot water systems, scale can trap Legionella and biofilm, providing a perfect growth medium that disinfectants cannot penetrate.

Scale deposits colonized by Legionella can continuously re-contaminate a system even after disinfection. Biofilm is a source of nutrients for L. pneumophila and can lead to taste and odor problems from the products of the bacteria’s metabolism.

Scale is a major cause of inefficiency in hot water systems. Scale on heat exchange surfaces dramatically reduces the heat transfer efficiency and promotes corrosion in the calorifiers and pipe. Descaling of a hot water system is time consuming and expensive. Water softeners can reduce scale, but there is growing concern over the increase to sometimes high levels of sodium in the water.

Bacteria & Scale Reduction

Many air conditioning and refrigeration plant systems use water for cooling. The heat generated by cooling coils is removed by water, which is passed through a water-cooling tower. These are recirculating systems, which operate at temperatures ideal for bacterial and algal growth and have plentiful supplies of nutrients. They have been highlighted as a major possible source of Legionnaires’ disease, mainly because of the large number of people that can be affected.

In a tower that is well designed and maintained, however, chances of problems with L. pneumophila are low. Most cases of outbreaks have occurred in towers that were badly designed and had little or no maintenance.

In cooling towers, temperature, hardness, pH, scale and corrosion are all factors that increase the chance of biofilm, algae and Legionella colonization. Many agents are used to control these factors, including scale and corrosion inhibitors, dispersants and biocides. Water softeners are sometimes used for hard water, which can cause a problem with foaming.

Biofilm is a major problem in cooling towers. Biofilm and scale can reduce the efficiency of a cooling system to the point that it no longer transfers heat. Health and safety officers recommend periodic chlorination and descaling of cooling towers. Chlorine, however, is not always compatible with other treatment chemicals such as corrosion inhibitors, is not effective in alkaline water, and can itself cause corrosion.

Some biocides are effective against L. pneumophila if used in sufficient concentration. Strains of L. pneumophila and other bacteria may become resistant to particular biocides, so dual or alternating biocides should be used.

Electronic Water Treatment

What is required in all water systems — cold, hot and process — is a method of continuously controlling scale deposition and a water treatment regime that prevents the growth of biofilm and bacteria, in particular, L. pneumophila. One method is electronic scale treatment, which couples scale deposition prevention with the chlorination of all water supplied to a building or factory, both hot and cold.

Electronic water treatment involves the fitting of electronic water descaling equipment at strategic points in the water system. Water treated by such systems prevents scale from forming in pipe and on heat transfer surfaces. The equipment also removes existing scale deposits over a period of time. There are many advantages to this non-intrusive engineering solution:

Normally linked to cooling towers, evaporative condensers, mist machines, humidifiers, whirlpool spas and showers, L. pneumophila is most commonly associated with the disease outbreak (legionellosis) that is caused by the inhalation of contaminated water in the form of aerosol spray that is smaller than 5 μm. Legionella bacteria thrive in stagnating water, such as in tanks, reservoirs, dead legs in piping systems and poor-flow areas. They require temperatures between 68°F and 113°F (under 68°F, they survive, but over 140°F, they are killed) and a supply of nutrients found in algae, rust, sludge and scale.

Disease Prevention

Health agencies continually draw attention to the risks and best practices for cooling water treatment for cooling towers and evaporative condensers. Conditions that affect the proliferation of Legionella include:

- The presence of scale deposits or algae growth in the water;

- Dead legs in the pipe or stagnation due to low use of outlets;

- Low temperature in potable hot water heaters and distribution systems;

- Stratification of water in heaters; and

- Inappropriate water treatment.

Managing the risks from Legionella in water systems requires a holistic approach and a suite of control measures underpinned by a suitable and sufficient risk assessment specific to the system in question. In areas with hard water, scale formation can be a problem unless properly managed, and can increase the likelihood of Legionella growth.

The Role of Scale

Scale, or limescale, is a hard, rock-like deposit of calcium or magnesium salts that forms in heat exchangers, cooling tower packing and other water-fed equipment as a result of heat and increased concentration factor. Scale formation impairs heat transfer, interferes with flow and cooling, and can be a breeding ground for Legionella.

The scaling tendency of a water supply depends on the hardness of the water; still, if not adequately treated, even relatively soft waters can become highly scaling when concentrated by evaporation. Poor scale control not only puts the cooling process at risk, but also can squander thousands of dollars in wasted energy, chemical and water charges.

Scale is a problem in both hot- and cold-water systems. Dripping taps can deposit scale in and around the tap, and with high ambient room temperatures provide an ideal growth medium for L. pneumophila. In hot water systems, scale can trap Legionella and biofilm, providing a perfect growth medium that disinfectants cannot penetrate.

Scale deposits colonized by Legionella can continuously re-contaminate a system even after disinfection. Biofilm is a source of nutrients for L. pneumophila and can lead to taste and odor problems from the products of the bacteria’s metabolism.

Scale is a major cause of inefficiency in hot water systems. Scale on heat exchange surfaces dramatically reduces the heat transfer efficiency and promotes corrosion in the calorifiers and pipe. Descaling of a hot water system is time consuming and expensive. Water softeners can reduce scale, but there is growing concern over the increase to sometimes high levels of sodium in the water.

Bacteria & Scale Reduction

Many air conditioning and refrigeration plant systems use water for cooling. The heat generated by cooling coils is removed by water, which is passed through a water-cooling tower. These are recirculating systems, which operate at temperatures ideal for bacterial and algal growth and have plentiful supplies of nutrients. They have been highlighted as a major possible source of Legionnaires’ disease, mainly because of the large number of people that can be affected.

In a tower that is well designed and maintained, however, chances of problems with L. pneumophila are low. Most cases of outbreaks have occurred in towers that were badly designed and had little or no maintenance.

In cooling towers, temperature, hardness, pH, scale and corrosion are all factors that increase the chance of biofilm, algae and Legionella colonization. Many agents are used to control these factors, including scale and corrosion inhibitors, dispersants and biocides. Water softeners are sometimes used for hard water, which can cause a problem with foaming.

Biofilm is a major problem in cooling towers. Biofilm and scale can reduce the efficiency of a cooling system to the point that it no longer transfers heat. Health and safety officers recommend periodic chlorination and descaling of cooling towers. Chlorine, however, is not always compatible with other treatment chemicals such as corrosion inhibitors, is not effective in alkaline water, and can itself cause corrosion.

Some biocides are effective against L. pneumophila if used in sufficient concentration. Strains of L. pneumophila and other bacteria may become resistant to particular biocides, so dual or alternating biocides should be used.

Electronic Water Treatment

What is required in all water systems — cold, hot and process — is a method of continuously controlling scale deposition and a water treatment regime that prevents the growth of biofilm and bacteria, in particular, L. pneumophila. One method is electronic scale treatment, which couples scale deposition prevention with the chlorination of all water supplied to a building or factory, both hot and cold.

Electronic water treatment involves the fitting of electronic water descaling equipment at strategic points in the water system. Water treated by such systems prevents scale from forming in pipe and on heat transfer surfaces. The equipment also removes existing scale deposits over a period of time. There are many advantages to this non-intrusive engineering solution:

- Energy use is greatly reduced due to heat exchange surfaces remaining free of scale deposits (just ¼ in. of scale increases energy costs by about 40%).

- Corrosion caused by scale deposits is eliminated.

- Extensive downtime and labor costs involved in descaling systems are eliminated.

- A source of colonization for biofilm and L. pneumophila is removed.

- Water distribution efficiency and pressure are increased by removal of scale deposits that can reduce pipe diameters considerably.