Railway Investigation Report R14D0011

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability.

Main-track collision

Canadian National yard assignment

and Canadian National freight train Q12111-21

Mile 3.5, Montreal Subdivision

Montréal, Quebec

Canadian National yard assignment

and Canadian National freight train Q12111-21

Mile 3.5, Montreal Subdivision

Montréal, Quebec

Summary

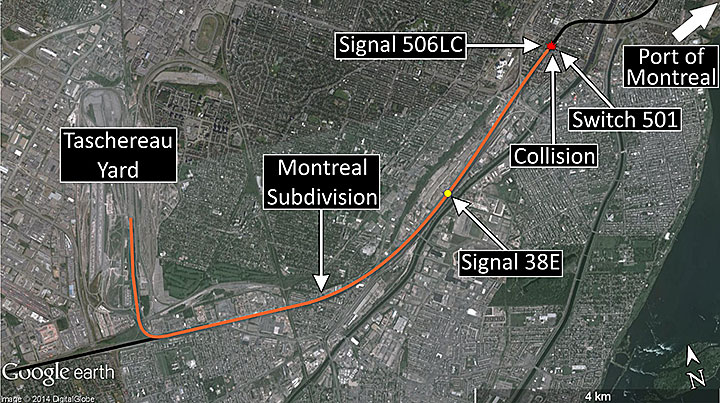

On 23 February 2014, a Canadian National yard assignment, controlled by a remote control locomotive, was travelling with 25 loaded cars on the “freight track” service track of the Montreal Subdivision in Montréal, Quebec. At about 0005, the yard assignment passed a stop signal and collided with train Q12111-21, which was travelling on the north track. Both trains, as well as the tracks they were travelling on, were damaged. There were no injuries.Le présent rapport est également disponible en français.

Factual information

The accident

On 22 February 2014 at about 2100,Footnote 1 a conductor and an assistant conductor began their shift at Canadian National's (CN) Taschereau Yard in Montréal, Quebec, on an extra yard assignment with locomotives CN 7208 and CN 7224. This assignment was operating without a locomotive engineer (LE) using a remote control locomotive system (BeltpackFootnote 2). The 2 crew members were familiar with the territory and met fitness and rest standards. They met the requirements of their respective positions and had been trained as locomotive operators using the remote control locomotive system.After reviewing the documentation regarding their train, the 2 employees went into locomotive CN 7224 where they left their bags containing the operations documents. They then armed the Beltpack and carried out the preliminary inspection and tests. The crew was to couple to 25 loaded grain cars that were on the east side of Taschereau Yard and bring them to a customer located next to the Port of Montreal, about 8 miles east of Taschereau Yard.

At about 2315, the locomotives being coupled to the cars, the crew was ready to leave Taschereau Yard as a transferFootnote 3 in accordance with the Canadian Rail Operating Rules (CROR). The 2 crew members positioned themselves in the cab of locomotive CN 7208, now located in the lead position. The locomotives remained in Beltpack mode, controlled by the conductor. The train weighed approximately 3500 tons and was approximately 1550 feet in length.

While leaving the yard, the conductor performed a running brake test to verify that the braking system was functioning. To do this, the brakes of the locomotives and cars were fully applied while the train was travelling at a speed of 11 mph. The train came to a stop in 32 seconds and in approximately 350 feet. Having determined that the braking system was responding adequately, the crew members resumed their trip towards the Port of Montreal.

Around 0003, while the yard assignment was travelling at 15 mph and was approximately 3000 feet from signal 506LC, the rail traffic controller (RTC) called the crew to cancel a general bulletin order (GBO).Footnote 4 Signal 506LC governs movements over switch 501 that connects the freight track to the north track. As both crew members had left their bags in locomotive CN 7224, the assistant conductor left the cab of the lead locomotive to retrieve the required form. During his absence, the conductor found the required document in locomotive CN 7208. He then stood up at the LE's control stand and began copying the RTC's instructions. In the following minutes, the yard assignment passed signal 506LC located 700 feet west of switch 501 leading to the north track. Upon returning to the lead locomotive, the assistant conductor drew the conductor's attention to the imminent collision. The emergency brakes were applied. However, the yard assignment was unable to stop before colliding with train Q12111-21 (train 121), a container train travelling westward on the north track (Photo 1).

At the time of the accident, it was cloudy and the temperature was 2°C.

Site examination

The collision occurred in the borough of Saint-Henri, Quebec, southwest of the city of Montréal. This neighbourhood is mainly made up of residential buildings, which, at some locations, border the railway right-of-way. There are 3 overpasses and 2 public crossings in Saint-Henri—one on Saint-Ambroise Street and one on de Courcelle Street.The 2 locomotives of the yard assignment derailed and came to a stop adjacent to switch 501, which connects the freight track to the north track. Lead locomotive CN 7208 sustained considerable damage on the right-hand side to the following components: steps, side ladders, handrails, brake rigging, brake piping and side platforms. Its fuel tank was punctured, causing a spill of approximately 4000 litres of diesel fuel. The first 2 cars (SOO 122215 and SOO 121820) derailed and were damaged on the south side. The steps, side ladders, end ladders and frames of the 2 cars were damaged.

The 2 derailed cars were re-railed first and left to the west of the site. The CN employees then focused on the locomotives. While a crane was lifting the front of locomotive CN 7208, its frame buckled immediately behind the cab (Photo 2). Because of this additional damage, CN classified that locomotive as non-repairable. After the parts that could be salvaged were removed, the locomotive was cut up on site.

Train 121 was damaged over a length of approximately 475 feet, from the 12th car to the 17th car, involving ladders, steps and frames. In addition, a few containers were crushed.

The freight track and the north track were damaged. The north rail of the freight track was ripped from its ties for 175 feet and was broken in several places. The mechanism of switch 501 was destroyed. In addition, the south rail on the north track had to be placed back onto its tie plates and re-spiked to re-establish the track gauge. The crossings on Saint-Ambroise and de Courcelle streets were blocked for about 2 hours.

Track information

The Montreal Subdivision consists of a double main track that runs from Cape (junction with the St-Hyacinthe Subdivision) at Mile 1.2 near Central Station in Montréal to Dorval, Quebec, at Mile 11.6. On this section of track, there are 8 controlled locationsFootnote 5 with several crossovers.Footnote 6 Train movements are governed by the centralized traffic control system (CTC) in accordance with the CROR, under the supervision of an RTC located in Montréal.The subdivision has 2 main tracks. On some sections, there are additional signalled tracks. For example, the signalled track (freight track) on which the yard assignment was travelling begins at Mile 3.5 and stretches to Mile 8.9. In the accident area, all tracks are at least Class 3Footnote 7 according to the Transport Canada-approved Track Safety Rules. The maximum allowable speed for the freight track is 30 mph. The subdivision is part of Canada's high-speed rail corridor between Québec, Quebec, and Windsor, Ontario. VIA Rail Canada Inc. (VIA) trains travelling to Ottawa, Ontario, Toronto, Ontario, and Northern Quebec travel on this subdivision after leaving Montréal's Central Station. Rail traffic consists of about 50 trains per day (freight trains and passenger trains), which represents approximately 60 million gross tons per year.

In the accident area, the track consists of 132-pound rail on 14-inch double-shouldered tie plates secured to the ties with 4 spikes. Every tie is box-anchored and the ballast is made up of ½- to 2-inch crushed stone.

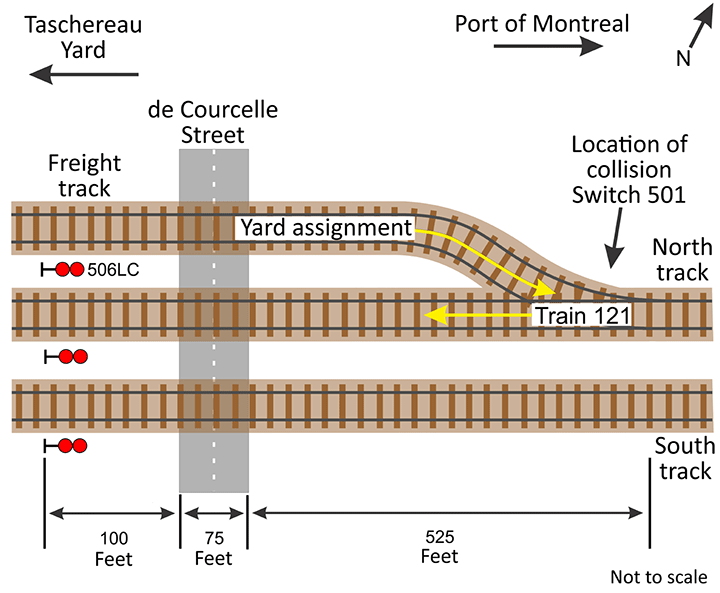

Yard assignment itinerary

From Taschereau Yard, the yard assignment went on the freight track to reach the north track of the Montreal Subdivision, at Mile 3.5 (Figure 1). The yard assignment was to wait for intermodal train 121, travelling westward on the north track, to pass. Once train 121 had passed, the yard assignment was to continue its trip eastward.The junction between the freight track and the north track is located at turnout 501, which is equipped with a dual-control switchFootnote 8 (Figure 2). This location is under the control of the RTC and train movements are governed by signals. Eastbound movements on the freight track that approach switch 501 encounter approach signal 38E and signal 506LC. Signal 506LC is located 700 feet west of switch 501, and signal 38E is about 6500 feet farther west. The sightline distance to signal 38E is 3600 feet, while that of signal 506LC is 1500 feet.

An examination of the CTC recordings revealed no operational malfunction of signals. Signal 506LC at Saint-Henri indicated a stop signal and approach signal 38E indicated “Clear to Stop.”Footnote 9

Sequence of events

Table 1 shows the time of recorded conversations between the conductor and the RTC as well as data from the yard assignment's locomotive event recorder.| Time | Event |

|---|---|

| 0003:16 | The RTC calls the yard assignment to cancel a GBO. |

| 0003:29 | Reset of the Beltpack vigilance system. |

| 0003:51 | The conductor begins copying the GBO cancellation. |

| 0003:57 | Signal 506LC becomes visible. |

| 0004:19 | Reset of the Beltpack vigilance system. |

| 0005:06 | The yard assignment passes signal 506LC. |

| 0005:12 | Reset of the Beltpack vigilance system. |

| 0005:18 | The conductor finishes the GBO cancellation. |

| 0005:19 | The assistant conductor returns to the lead locomotive and draws the conductor's attention to the imminent collision. |

| 0005:21 | The emergency brakes are applied. |

| 0005:29 | Locomotive CN 7208 collides with train 121. |

| 0005:31 | The yard assignment comes to a stop. |

Employee training

At CN, new employees in the train operations group initially received training as conductor, which was subsequently complemented by locomotive engineer (LE) training. LE training required a minimum of 18 months of experience as conductor and lasted 6 months.Beltpack training was part of the initial training given to new conductors hired in terminals that used Beltpack locomotives. That training, which lasted a week, was made up of a classroom component and a practical component under the supervision of an instructor. At the end of their training, participants had acquired the following knowledge and skills:

- Safely start and shut down a Beltpack locomotive.

- Identify the Beltpack components on a locomotive and the operator control unit (OCU).

- Set up the locomotive and Beltpack for operation.

- Conduct locomotive inspections and carry out preliminary tests.

- Identify, troubleshoot and reset faults that may occur during a work shift.

- Control speed and braking of a train.

The conductor started his career at CN in late September 2011, and the assistant conductor, in February 2013. Both were hired in the train operations group and underwent Beltpack operator training during their initial training. Neither had received LE training.

Canadian Rail Operating Rules

CN train movements are operated in accordance with the CROR. Rule 34 (Fixed Signal Recognition and Compliance) reads as follows:[…]Also, Rule 136 (Copying, Repeating, Completing and Cancelling) stipulates that:

(b) Crew members within physical hearing range must communicate to each other, in a clear and audible manner, the indication by name, of each fixed signal they are required to identify. Each signal affecting their movement must be called out as soon as it is positively identified, but crew members must watch for and promptly communicate and act on any change of indication which may occur.

The following signals/operating signs must be communicated:

(i) Block and interlocking signals;Footnote 10

[…]

[…]

(b) GBO, authorities or instructions must not be copied by the employee operating moving equipment or track units, if it will interfere with the safe operation of such equipment or track unit.

Compliance with signal indications

Following the investigation into the collision between 2 Canadian Pacific Railway (CP) trains in 1998, near Notch Hill, British Columbia (TSB Railway Investigation Report R98V0148), the Board determined that the backup safety defences for signal indications were inadequate and recommended that:The Department of Transport and the railway industry implement additional backup safety defences to ensure that signal indications are consistently recognized and followed by crew members.CP had taken steps to correct the deficiency by implementing procedural improvements as part of its crew resource management practices. While there has been some safety benefit, administrative or procedural defences are not always adequate to protect against an operating crew's misinterpreting or misperceiving wayside signal indications. TC and the railways are exploring the potential for current locomotive fleet computer systems to include signal recognition and air brake control capabilities. However, to date, there has been no formal strategy developed to adapt either emerging technology or existing on-board computer systems to provide fail-safe physical train control defences. Therefore, the Board reassessed the response to Recommendation R00-04 to remain Satisfactory in Part.

TSB Recommendation R00-04, issued February 2001

In addition to the installation of CTC, railways have adopted various other defence mechanisms to help prevent accidents. However, these defences are inadequate in situations where the train crew misinterprets or misperceives a signal indication or does not apply, or misapplies, an operating rule.

Following another accident resulting from a signal being misperceived or misinterpreted at Aldershot, Ontario,Footnote 11 in February 2012, the Board recommended that:

The Department of Transport require major Canadian passenger and freight railways implement physical fail-safe train controls, beginning with Canada's high-speed rail corridors.TC has accepted that recommendation and will request a study and a written report by the Advisory Council on Rail Safety (ACRS). The effect of TC's initiative will not be fully known until the ACRS report has been filed, the options and recommendations are made public, and a decision to take concrete actions is announced by TC. Since TC's response does not provide a clear plan to mitigate the safety deficiencies, the Board assessed the response to Recommendation R13-01 as Satisfactory in Part.

TSB Recommendation R13-01, issued June 2013

Watchlist

The Watchlist sets out the issues posing the greatest risk to Canada's transportation system and aims to focus the attention of industry and regulators on the problems that need addressing today. Given that a risk of collision or derailment exists if rail signals are not consistently recognized and followed, the TSB included this deficiency on its Watchlist in 2012 and in 2014. Since 2002, there has been an average of 30 occurrences per year in which a signal indication was misidentified, misinterpreted or not immediately recognized, thereby contributing to the occurrence. If signal indications are not followed, the CTC system cannot ensure that trains on the same line are separated appropriately. The CTC system does not provide any warning that a train may be passing beyond a restricted location, nor does it provide automatic means to slow or stop a train before it passes a stop signal or other points of restriction.Introduction of remote control locomotives

A traditional yard crew comprises an LE as well as a conductor and an assistant conductor posted on the ground to perform yard switching. The employees on the ground transmit their instructions to the LE who controls the locomotive. Use of the Beltpack and other similar technologies enables the crew to control the locomotive remotely using the OCU, rather than relying on instructions communicated by employees on the ground. Beltpack movements are governed by the CROR.In the late 1980s, this technology was introduced in Canada and allowed by TC. When the remote control locomotive was first introduced, systems of this type were used mainly for controlling locomotives during humping operations.Footnote 12 In the mid-1990s, use of the Beltpack was extended to flat switching in CN yards and on main track. Nowadays, on a daily basis, many yard crews travel on main track using Beltpack to move either from one yard to another or to travel to a customer siding to perform switching.

When the Beltpack was introduced, several CROR rules called for joint observation by the conductor and the LE; this meant that Beltpack trains were restricted to non-main tracks where these rules did not apply. Railway rules were then adapted and special instructions were added by CN to allow train crews to travel on main track without an LE.

In May 2008, the CROR were revised and the term “remote control operator” was added to the definitions. In addition, several rules were modifiedFootnote 13 to allow certain tasks that were formerly carried out by the LE to be performed by another crew member. Since this revision, the CROR allow all railway companies in Canada to travel on main track with a Beltpack crew.

Instructions for using a Beltpack remote control system

During Beltpack operations, the operator uses an OCU (Photo 3), a 3- to 5-pound box attached to the operator's safety vest. Radio commands transmitted by the OCU are received and processed by a computer on board the locomotive. The Beltpack OCU is equipped with (but not limited to) a speed selector, a forward and reverse selector, and a brake selector that includes an emergency brake feature.CN's General Operating Instructions (GOIs), section 6, governing Beltpack operations defines a remote control operator as an operating employee who, through training, experience and knowledge, is qualified to perform switching operations and remotely control a movement using the Beltpack technology.

Beltpack operators choose a pre-selected speed of up to 15 mph, after which the operator does not have to manipulate the controls as it is the Beltpack that takes the required actions to reach and maintain that speed. The maximum speed at which a movement can travel in remote control locomotive mode is 15 mph. The system applies either the throttle or the brakes of the locomotives to maintain the pre-selected speed at ± 0.5 mph. The system's adaptation to train and terrain characteristics is done reactively, without taking the train length, tonnage or slack into account.

In contrast, operating a locomotive is a complex task that requires LEs to know the characteristics of the train they are operating as well as those of the territory in which they are travelling. LEs must anticipate the train's response and must adapt its operation to negotiate changes in terrain as well as to comply with signal indications and RTC's instructions. To do this, they use the throttle and brakes. In addition, to reduce the in-train forces and those that come into play between the train and the track, changes to the train speed must be planned and gradual. Trains can be operated at speeds of up to 100 mph; the speed varies according to the track and the train type.

Use of the Beltpack in Montréal

At the time of the accident, there were 14 Beltpack crews located in the Montreal service area. Of these 14 assignments, 3 travelled on main track daily to perform switching. These Beltpack crews travelled mainly on the St-Laurent and Montreal subdivisions and over a distance of about 10 miles. On average, trains consisted of two 4-axle locomotives and between 25 and 30 cars, had a length of 1300 feet and weighed approximately 2600 tonnes. However, there were no length or tonnage restrictions of Beltpack movements when they travelled on main track.Vigilance systems

Modern vigilance systems monitor locomotive speed, brake cylinder air pressure and the actions of the LE at the control stand to determine the frequency at which the system must be reset. Extended periods (between 30 seconds and 2 minutes) without LE action set off the vigilance system. A visual indicator, followed by an audible alarm, prompts the LE to take action. The LE must reset the system, either by operating a control on the locomotive control stand (e.g. bell, throttle, radio) or by pressing the reset button. If the LE does not do so, a penalty brake applicationFootnote 14 is triggered to stop the movement.The Beltpack OCU has a vigilance system fitted with an audible alarm that sounds after 50 seconds of inactivity. Any activity by the operator resets the countdown. If the operator does not acknowledge the alarm, the locomotive and car brakes are fully applied. During operations that use the Beltpack, it is the Beltpack's vigilance system that becomes operational rather than that of the locomotive.

Assessments of the risks associated with the Beltpack

The TC publication entitled Railway Safety Management Systems – Guide: A Guide for Developing, Implementing and Enhancing Railway Safety Management Systems (TP 15058E) identifies 3 steps in risk management: identification of issues and concerns, risk estimation, and risk evaluation in order to determine whether the risks identified are tolerable, tolerable with mitigation, or unacceptable. The guide indicates that risk assessments should be documented, including any control strategies implemented. The guide also stresses that companies must analyze any new activities and major operational changes. In addition, it states that a complete analysis of existing operations is not required provided that current risk mitigation strategies are documented. The guide also states:For existing operations, many of the risks will have already been considered and risk control strategies will form part of the railway's current rules, standards, procedures and operating practices. In this case, the risk assessment process would document this link and then focus on the results of accident and incident investigations, safety data analysis, complaint follow-up, inspections, and audits to ensure that the risk is being mitigated to an acceptable level. This analysis should point railway companies to areas where they could undertake initiatives beyond their current practices in an effort to improve their overall safety performance.Footnote 15Since 2001, CN has carried out risk assessments relating specifically to general Beltpack operations and at locations that present special challenges in order to establish risk-mitigation procedures. However, no assessment of this type has been carried out in the Montreal service area and nothing indicates that the lessons learned elsewhere are applicable to local conditions in Montréal. Moreover, CN has no formal operational restriction on length, tonnage or track topography for Beltpack trains.

American study on Beltpack

The introduction of remote control locomotives in the United States led the Federal Railroad Administration (FRA) to carry out a study on their use. The study focused on the training of remote control operators, the operation of trains with a remote control locomotive and their impact on safety. The report, which was completed in 2006, concluded that remote control locomotive technology had limited application to main-track operations and that more in-depth training would be required for main-track operations. In addition, the FRA recommended that railways adopt operational restrictions on the length, tonnage, and territory characteristics.Site clean-up

The fuel tank of locomotive CN 7208 was punctured, causing a spill of 4000 litres of diesel fuel (UN 1202). The city of Montréal fire department and staff from the ministère du Développement durable, de l'Environnement, de la Faune et des Parcs (ministry of sustainable development, environment, wildlife and parks) responded and took the following measures:- Absorbent material spread by the firefighters contained the spill, limiting it to the road bordering the track to the north.

- About 2800 litres of fuel was pumped immediately after the accident and another 1000 litres was retrieved in the ensuing days.

- Contaminated snow, ice, and ballast were retrieved using a vacuum tanker truck.

Analysis

No track or equipment defects were considered contributory to the accident. An examination of the centralized traffic control system (CTC) recordings revealed no operational malfunction of signals. Consequently, the analysis will focus on the operation of the train, the Beltpack, and human factors.The accident

Eastbound movements approaching switch 501 meet approach signal 38E, then signal 506LC. Approach signal 38E is visible from 3600 feet and signal 506LC, from 1500 feet. These sightlines were sufficient for the yard assignment crew to see the signals, identify them and comply with them. An examination of the CTC system recordings revealed no operational malfunction of signals. Signal 506LC at Saint-Henri displayed a stop indication. The conductor and assistant conductor had identified signal 38E and confirmed among themselves that it indicated “Clear to Stop.” Given the result of the running brake test, the crew did not need to reduce the train speed to be able to stop the train if signal 506LC displayed “Stop.” The crew members were in a position to continue at a speed of 15 mph until signal 506LC entered their field of vision, and then react accordingly. However, the stop indication displayed by signal 506LC was not seen by the conductor and, consequently, steps were not taken to comply with it. The yard assignment passed signal 506LC while it was displaying a stop signal, occupied switch 501 and collided with train 121, which was travelling on the adjacent track.Recording of the rail traffic controller's instructions

Under normal circumstances, instructions from the rail traffic controller (RTC) are recorded immediately as they may have an immediate impact on train operations. However, Rule 136 of the Canadian Rail Operating Rules (CROR) stipulates that general bulletin orders (GBOs), authorities or instructions must not be copied by the employee operating moving equipment or track units if this will interfere with the safe operation of such equipment or track unit. This rule implies that the current situation and the risks must be assessed before copying the RTC's instructions. Since the track was clear and signal 506LC was not visible, the conductor believed that copying the instructions would not put the movement at risk as he would be able to take the measures required to comply with the indication of signal 506LC at the proper time. However, by standing up at the locomotive engineer's (LE) control stand to copy the RTC's instructions, the conductor was no longer facing the direction of the movement and his field of vision through the windows was restricted; he therefore did not notice signal 506LC indicating stop and was unable to stop his train to prevent the collision.During the 10 minutes preceding the accident, the remote control operator had not been required to take any action to maintain the yard assignment's speed, other than reset the vigilance system. When the RTC contacted the train crew to cancel a GBO, the yard assignment was approximately 3000 feet from signal 506LC. The train was travelling on a section of track located in the median of a highway, having little public access and no level crossings, and sustained visual attention was not required. Moreover, the slow speed of the train and the short braking distance required to stop it likely influenced the conductor's decision to copy the RTC's instructions while he was alone in the lead locomotive and the train was moving.

Normally, the employee who is not at the controls of the movement, the assistant conductor in this case, copies the instructions. However, the assistant conductor had gone to the second locomotive to retrieve the correct form to record the GBO cancellation, leaving the conductor alone in the lead locomotive. The conductor's main task was to monitor the track and control the movement using the Beltpack. Consequently, the task of copying the RTC's instructions was prioritized over observation of the track as the train approached signal 506LC, which led to the collision.

Prioritization of tasks – prospective memory

The indication of signal 38E, “Clear to Stop,” was an instruction to be executed later; the information—to approach the next signal, being prepared to stop—had to be memorized for a later task. This information is memorized using prospective memory, the memory that reminds one to perform a task that has been put off until later.Footnote 16 When a train is travelling on the main track, many simultaneous tasks can require the attention of the crew members. This is why crew members assess their circumstances and prioritize the tasks they perform. Sometimes, a crew may inadvertently spend too much time completing a task of lesser importance before moving on to a higher-priority task or even allowing the less important task to take precedence over a critical task that has been retained in prospective memory.Footnote 17 In addition, once a task has been started, there is a propensity to want to complete it. The communication from the RTC resulted in an interference (distraction) while the yard assignment was approaching signal 506LC.Non-compliance with stop signal

In the absence of the second crew member, the yard assignment's compliance with signal 506LC relied solely on the conductor's capacity to see the signal, recognize its indication and take the appropriate measures. Once the conductor was alone in the lead locomotive, the additional administrative defence provided by CROR Rule 34, as well as the synergy of working as a team, were no longer in place.For over a decade, the TSB has had an outstanding recommendation calling for additional defences in signalled territory to ensure that signal indications are consistently recognized and followed. In the absence of additional physical fail-safe train controls in signalled territory, the existing defences proved inadequate to prevent the collision.

Beltpack operation on main tracks

The Beltpack automatically controls train speed so the operator does not have to manipulate the throttle or brakes. As a result, the operation of trains in Beltpack mode is easier and requires less experience than that of conventional trains. However, as train tonnage and length increases, its operation becomes more complex. An examination of data from the yard assignment's event recorder showed that, in a period of 2 minutes, the Beltpack performed 35 throttle changes between position No. 1 and position No. 7 while on relatively flat terrain. This high number of throttle changes was due to the sensitivity of the Beltpack, which reacted to the slightest variation in acceleration by moving the throttle to maintain the pre-selected speed. The system's adaptation to train and terrain characteristics is done reactively, without taking the train length, tonnage or slack into account. Manipulations of this type lead to a less fluid operation and increased slack action, which can generate internal stresses in the train and increase the risk of damage to couplers and the risks of derailment, in particular in movements having high and unevenly distributed tonnage.The 2006 study by the United States Federal Railroad Administration (FRA) on the use of remote control locomotives concluded that remote control locomotive technology had limited application to main-track operations and that a more in-depth training would be required for main-track operations. In addition, the FRA advocated that railways adopt operational restrictions on length, tonnage, and territory characteristics. However, the recommendations of this study have not been followed.

Since 2001, CN has conducted several risk assessments to establish procedures to mitigate the risks of Beltpack operations. However, no in-depth study has been carried out to assess the restrictions of tonnage and length of Beltpack trains on main track. Notwithstanding the reasons that can explain why a risk assessment has not been conducted, it remains that such a systemic, documented analysis would make it possible to ascertain, for example, whether restrictions on train tonnage and length should be set, or whether additional training for conductors travelling on main track is necessary. If a thorough analysis of the risks is not carried out and criteria are not established for the operation of Beltpack trains on main track, the risks involved in this type of operation will not all be identified and appropriate mitigation measures will not be implemented to protect the public.

Effect of the Beltpack on detection performance

During Beltpack operations, the Beltpack vigilance system becomes operational rather than that of the locomotive. Unlike the vigilance system of a locomotive where the LE is sitting at the control stand, a position where he/she is prone to look ahead, a Beltpack operator can reset the vigilance system from any position, which could lead to distract his/her attention from the track. Moreover, it is recognized that the automation of tasks, essentially the control of the train speed in the case of the Beltpack, can cause operators to be more easily distracted, to the detriment of detection performanceFootnote 18 and visual attentionFootnote 19 factors. Although Beltpack operations are used over relatively short distances and task automation is limited, this type of operation can nonetheless affect operators' vigilance and visual attention, thereby increasing the risk of accidents.Assessment of risks on the Montreal Subdivision

The Montreal Subdivision is one of the busiest corridors in Canada, containing multiple tracks on which about 50 trains operate daily, including high-speed passenger trains. In addition, the presence of several controlled locations and 2 crossings, the proximity of tracks to residential buildings and the high number of pedestrians close to the railway right-of-way call for heightened vigilance from train crews. CN has carried out risk assessments on Beltpack operations at locations that present special challenges, but not on the Montreal Subdivision, even though the operation of trains on this subdivision encounters unique conditions. Moreover, there is nothing to indicate that lessons learned elsewhere are applicable to the conditions of the Montreal Subdivision. Such a risk assessment could have established that additional training and a sufficient level of experience were required before an employee was allowed to travel on main track in Beltpack mode. In addition, operational restrictions on train length, train tonnage and particular territory characteristics could have been identified. Consequently, given that CN had not conducted any risk assessment on Beltpack operations on the Montreal Subdivision, the particular risks of this subdivision were not identified; therefore, there was no additional restriction on the Beltpack movement.Site clean-up

The city of Montréal fire department and staff of the ministère du Développement durable, de l'Environnement, de la Faune et des Parcs responded appropriately to mitigate the spill of 4000 litres of diesel fuel and the damage caused during the cutting up of the locomotive. The monitoring program that was put in place made it possible to verify the soil quality and ensure that all the contaminated snow and soil was excavated and removed from the derailment site for treatment. Consequently, the implemented response plan and the remediation of the derailment site were appropriate, thereby minimizing environmental impact.Findings

Findings as to causes and contributing factors

- The yard assignment passed signal 506LC while it was displaying a stop signal, occupied switch 501 and collided with train Q-12111-21, which was travelling on the adjacent track.

- By standing up at the locomotive engineer's control stand to copy the rail traffic controller's instructions, the conductor was no longer facing the direction of the movement and his field of vision through the windows was restricted; he therefore did not notice signal 506LC indicating stop and was unable to stop his train to prevent the collision.

- The slow speed of the train and the short braking distance required to stop it likely influenced the conductor's decision to copy the rail traffic controller's instructions while he was alone in the lead locomotive and the train was moving.

- The task of copying the rail traffic controller's instructions was prioritized over observation of the track as the train approached signal 506LC, which led to the collision.

- The communication from the rail traffic controller resulted in an interference (distraction) while the yard assignment was approaching signal 506LC.

- Once the conductor was alone in the lead locomotive, the additional administrative defence provided by Canadian Rail Operating Rules Rule 34 as well as the synergy of working as a team were no longer in place.

Findings as to risk

- If a thorough analysis of the risks is not carried out and criteria are not established for the operation of Beltpack trains on main track, the risks involved in this type of operation will not all be identified and appropriate mitigation measures will not be implemented to protect the public.

- Although Beltpack operations are used over relatively short distances and task automation is limited, this type of operation can nonetheless affect operators' vigilance and visual attention, thereby increasing the risk of accidents.

Other findings

- Given that Canadian National had not conducted any risk assessment on Beltpack operations on the Montreal Subdivision, the particular risks of this subdivision were not identified; therefore, there was no additional restriction on the Beltpack movement.

- The implemented response plan and the remediation of the derailment site were appropriate, thereby minimizing environmental impact.

Safety action

Safety action taken

Canadian National (CN) conducted its own investigation into this derailment. CN's findings from the investigation were shared and discussed during a weekly Greater Montréal Area safety call, as well as a national CN safety call.This report concludes the Transportation Safety Board's investigation into this occurrence. The Board authorized the release of this report on 03 August 2015. It was officially released on 06 August 2015.

Appendices

Appendix A – Locomotive event recorder data

| Time* | Mile | Throttle position | Time during which the throttle was not changed |

|---|---|---|---|

| 2246:24 | 4.17 | 6 | - |

| 2246:25 | 4.17 | 5 | 1 second |

| 2246:26 | 4.16 | 5 | - |

| 2246:31 | 4.14 | 5 | - |

| 2246:36 | 4.12 | 6 | 11 seconds |

| 2246:36 | 4.12 | 6 | - |

| 2246:36 | 4.12 | 4 | <1 second |

| 2246:40 | 4.11 | 3 | 4 seconds |

| 2246:40 | 4.11 | 7 | <1 second |

| 2246:40 | 4.11 | 5 | <1 second |

| 2246:40 | 4.11 | 6 | <1 second |

| 2246:40 | 4.11 | 6 | - |

| 2246:40 | 4.11 | 4 | <1 second |

| 2246:44 | 4.09 | 3 | 4 seconds |

| 2246:44 | 4.09 | 7 | <1 second |

| 2246:44 | 4.09 | 5 | <1 second |

| 2246:46 | 4.08 | 6 | 2 seconds |

| 2246:46 | 4.08 | 6 | - |

| 2246:46 | 4.08 | 4 | <1 second |

| 2246:47 | 4.08 | 4 | - |

| 2246:52 | 4.06 | 4 | - |

| 2247:04 | 4.01 | 4 | - |

| 2247:05 | 4.00 | 3 | 19 seconds |

| 2247:07 | 3.99 | 4 | 2 seconds |

| 2247:09 | 3.98 | 4 | - |

| 2247:34 | 3.88 | 3 | 27 seconds |

| 2247:35 | 3.88 | 4 | 1 second |

| 2247:47 | 3.83 | 3 | 12 seconds |

| 2247:48 | 3.82 | 4 | 1 second |

| 2247:55 | 3.79 | 4 | - |

| 2248:01 | 3.77 | 4 | - |

| 2248:08 | 3.74 | 3 | 20 seconds |

| 2248:10 | 3.73 | 4 | 2 seconds |

| 2248:10 | 3.73 | 3 | <1 second |

| 2248:11 | 3.73 | 4 | 1 second |

| 2248:15 | 3.71 | 3 | 4 seconds |

| 2248:17 | 3.70 | 4 | 2 seconds |

| 2248:18 | 3.70 | 3 | 1 second |

| 2248:20 | 3.69 | 4 | 2 seconds |

| 2248:21 | 3.68 | 3 | 1 second |

| 2248:24 | 3.67 | 4 | 3 seconds |

| 2248:25 | 3.67 | 3 | 1 second |

| 2248:27 | 3.66 | 4 | 2 seconds |

| 2248:27 | 3.66 | 2 | <1 second |

| 2248:30 | 3.65 | 1 | 3 seconds |

| 2248:30 | 3.65 | 3 | <1 second |

| 2248:34 | 3.63 | 4 | 4 seconds |

| 2248:34 | 3.63 | 2 | <1 second |

Footnotes

- Footnote 1

-

All times are Eastern Standard Time.

- Footnote 2

-

Beltpack is the trademark designating the technology that enables

locomotives to be controlled remotely; it was developed and marketed by

CANAC Railway Services Inc., a former Canadian National subsidiary.

- Footnote 3

-

“An engine with or without cars operating on main track at speeds

not exceeding 15 MPH and need not be TIBS [Train Information and Braking

System] equipped.” (Transport Canada, TC O‑0‑167, Canadian Rail Operating Rules, Definitions).

- Footnote 4

-

General bulletin order (GBO) 2964 cancelling GBO 2810, which

restricted the speed to 10 mph at Mile 1.76 on the south main track.

- Footnote 5

-

“A location in CTC [centralized traffic control system] the limits

of which are defined by opposing controlled signals [controlled by the

rail traffic controller].” (Transport Canada, TC O‑0‑167, Canadian Rail Operating Rules, Definitions).

- Footnote 6

-

“A track joining adjacent main tracks, or a main track and another track.” (Transport Canada, TC O-0-167, Canadian Rail Operating Rules, Definitions).

- Footnote 7

-

Allowing a speed of up to 40 mph for freight trains and 60 mph for passenger trains.

- Footnote 8

-

“A switch equipped for powered and hand operation.” (Transport Canada, TC O-0-167, Canadian Rail Operating Rules, Definitions).

- Footnote 9

-

“Proceed, preparing to stop at next signal.” (Transport Canada, TC O‑0‑167, Canadian Rail Operating Rules, Rule 411).

- Footnote 10

-

An arrangement of signals and signal appliances that are

interconnected so that they can be operated successively in the desired

order (e.g. switches, bridges, crossovers, level crossings, etc.).

- Footnote 11

-

TSB Railway Investigation Report R12T0038.

- Footnote 12

-

Yard characterized by the presence of a manmade hump overlooking a

wide stretch of receiving tracks and switches; trains are hauled up the

hump by a locomotive, then uncoupled and allowed to run under gravity

towards the receiving yard tracks.

- Footnote 13

-

Canadian Rail Operating Rules rules 34(c), 85, 135, 147(b),

147(c), 302(b), 302.2(d), 302.3(b), 303, 309(b), 567.2(b), 569(b),

571(a), 577(d), 604(c), 609(b), 610(c), 618.1(b).

- Footnote 14

-

The brake pipe empties and locomotive and car brakes are fully applied.

- Footnote 15

-

Transport Canada, TP 15058E, Railway Safety Management Systems – Guide: A Guide for Developing, Implementing and Enhancing Railway Safety Management Systems (November 2010), p. 25, available at: http://www.tc.gc.ca/eng/railsafety/guide-sms.htm (last accessed 10 July 2015).

- Footnote 16

-

J.R. Wilson, People and Rail Systems: Human Factors at the Heart of the Railway (Ashgate Publishing, Ltd., Aldershot: 2007), Chapter 9: Cognitive Workload of Train Drivers, pp. 91–101.

- Footnote 17

-

Ibid.

- Footnote 18

-

G. Salvendy, Handbook of Human Factors and Ergonomics, fourth edition (John Wiley & Sons: 2012), Chapter 59: Human Factors and Ergonomics in Automation Design, pp. 1617–1619.

- Footnote 19

- M.R. Endsley, “Automation and Situation Awareness” in R. Parasuraman and M. Mouloua (eds), Automation and Human Performance: Theory and Applications (Lawrence Erlbaum Associates, Mahwah: 1996), pp. 163–181.