The Changing Role of LNG in the United States: From Importers of LNG to Exporters.

As recently as 2008, demand for natural gas in the United States greatly exceeded domestic supplies. To meet demand, a large amount of natural gas was imported by pipeline from Canada and several terminals to receive liquefied natural gas from Africa, South America and the Middle East were built or planned on the eastern and Gulf coasts of the United States. Construction costs for each of these terminals was billions of dollars.

Then, the use of hydraulic fracturing and horizontal drilling caused an enormous surge in the production of domestic natural gas. A flood of new production from shale plays such as the Marcellus, Haynesville, Fayetteville, Barnett and others overwhelmed the market. Domestic natural gas prices fell from over ten dollars per thousand cubic feet down to below two dollars. The terminals built to receive the liquefied natural gas are now underutilized or idle.

Now, several companies are working to convert the LNG import terminals into terminals suitable to export gas. Their goal is to move the gas to Asian markets where prices are much higher. Although this sounds like a fantastic idea, a tremendous amount of gas has recently been discovered off Australia, Indonesia and Southern Asia. These areas have a significant transportation advantage over shipments leaving the Atlantic or Gulf coast of the United States. Converting the US import terminals into export facilities is a gamble without long-term contracts.

Recently though, a $7billion dollar investment is being implemented to construct an LNG facility off the coast of Oregon. This transport route is expected to provide cost advantages over the Gulf Coast or Atlantic Coast routes.

What is LNG?

LNG or liquefied natural gas is natural gas that has been temporarily converted into a liquid. This is done to save space - 610 cubic feet of natural gas can be converted into a single cubic foot of LNG. Converting natural gas into LNG makes it easier to store and easier to transport where pipelines are not available.

A refrigeration process is used to condense natural gas into LNG by cooling it to a temperature of minus 260 degrees Fahrenheit. This refrigeration process is usually accompanied by treatments that remove water, carbon dioxide, hydrogen sulfide and other impurities.

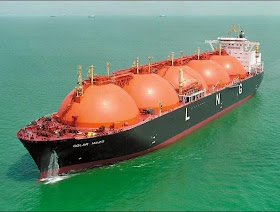

To maintain this low temperature during storage and transport, LNG must be placed into cryogenic tanks - heavily insulated tanks equipped with refrigeration units.

When a shipment of LNG reaches its destination or when LNG is being removed from storage it must be regasified. This is done by heating the LNG and allowing it to evaporate back into natural gas. Regasification is usually done at a facility where the gas can be placed into storage or directly into a pipeline for transport.

Liquefaction and Regasification Terminals

There are two types of LNG terminals: 1) terminals that convert natural gas into LNG, and, 2) terminals that convert LNG back into natural gas. These are called liquefaction terminals and regasification terminals, respectively. Liquefaction terminals are on the export side of transactions and regasification terminals are on the import side of transactions.

Liquefaction terminals generally receive natural gas by pipeline from a well field. Before it is liquefied the gas must be cleaned of water, carbon doixoide, hydrogen sulfide and other impurities that might freeze, become corrosive or interfere with the liquefaction process. Once liquefied the LNG is sent by pipeline to a LNG carrier ship or into storage to await transport.

Regasification terminals receive natural gas - usually by ship - from other areas. At a regasification terminal the LNG might be temporarily stored or sent directly to a regasification plant. Once regasified it is sent by pipeline for distribution or placed in temporary storage until it is needed.