EMERGING RISKS: VOC

OFF-GASSING OF COMPOSITE PRODUCTS (SUCH AS WIND TURBINES); INHALATION OF

STYRENE VAPORS DURING THE MANUFACTURE OF WIND TURBINE BLADES

There are a number of hazards associated with the manufacture of the wind turbine blades and other components, especially the inhalation of styrene vapors during the coating of the blades. Following the record number of fatalities of workers in 2011, the U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) and American Wind Energy Association (AWEA) recognize the value of establishing a collaborative relationship to foster safer and more healthful American workplaces. To that end, OSHA and AWEA formed an “Alliance” to provide AWEA’s members and others working in wind energy industry maintenance and operations with information, guidance, and access to training resources that will help them protect the health and safety of workers, particularly by reducing and preventing exposure to fall, electrical, and crane hazards, and understand the rights of workers and the responsibilities of employers under the Occupational Safety and Health Act. OSHA also officially focused its attention onto the wind energy industry, meaning more inspections and enforcement actions against violators of worker safety laws.

The participants

intend to work together to achieve the following outreach and communication

goals:

- To develop information on the recognition and prevention of workplace hazards, and to develop ways of communicating such information (e.g., print and electronic media, electronic assistance tools, and OSHA’s and the AWEA’s Web sites) to employers and workers in the industry.

- To speak, exhibit, or appear at OSHA’s or AWEA’s conferences, local meetings, or other events.

- To share information among OSHA personnel and industry safety and health professionals regarding AWEA’s good practices or effective approaches through training programs, workshops, seminars, and lectures (or any other applicable forum) developed by the participants.

OSHA’s Alliances

provide parties an opportunity to participate in a voluntary cooperative

relationship with OSHA for purposes such as raising awareness of OSHA’s

rulemaking and enforcement initiatives, training and education, and outreach

and communication. These Alliances have proved to be valuable tools for both

OSHA and its Alliance participants. By entering into an Alliance with a party,

OSHA is not endorsing or promoting, nor does it intend to endorse or promote,

any of that party’s products or services.

The turbine installation and maintenance fall accidents are very similar to the accidents occurred during the installation, disassembly or maintenance of telecommunication towers. Nineteen workers have died in communication tower accidents since 2013, a sharp rise from recent years. In 2014, over 20 workers have fallen to their deaths during cell tower operations. OSHA has announced new changes in how it polices the industry, including tracking what cell carrier or tower owner subcontractors had been working for when accidents occurred.

Blade Maker Cited 8th Time in 4 Years

Thursday, April 28, 2011

A wind turbine blade

manufacturer with a history of federal safety violations, including some

related to a 2010 death, is now accused of having employees work in a confined

space filled with excessive levels of styrene.

The Occupational

Safety and Health Administration has issued 11 serious, repeat and willful

citations and proposed $136,500 in penalties against LM Wind Power Blades Inc.,

of Grand Forks, ND.

LM, formerly known as

LM Glasfiber, is already contesting three OSHA cases, including the one

involving the fatality, at the same plant. OSHA records also show four closed

cases with LM since 2007, including three at the Grand Forks facility.

“We take this very

seriously and will continue to collaborate with authorities to ensure we

maintain a safe working environment for all our employees,” an LM spokeswoman

said in an email Thursday (April 28). “At this point, however, it is premature

to say what our response will be.”

Chemical Exposures,

Confined Space

The new allegations

stem from an October 2010 inspection. Over two days, the agency said, the

company allowed employees to remain at work inside the confines of a giant

wind-turbine blade amid exposures to styrene that reached 2,195 parts per

million (ppm), triggering air-quality alarms.

Styrene is a

hazardous chemical used in fiberglass production; OSHA’s short-term exposure

limit is 600 ppm; for an eight-hour shift, it is about 100 ppm, an OSHA

spokesman said.

Supervisors allowed

the work to continue for hours, despite air-quality readings showing excessive

exposures, and did not evacuate the confined space as required—willful

violations, OSHA said, that demonstrate “intentional disregard” for the law or

“plain indifference” to employee safety and health. Those two citations carry

$70,000 in penalties.

“The employer is well

aware of OSHA requirements and has continued a pattern of failing to comply with

them,” said Tom Deutscher, OSHA's area office director in Bismarck. “Despite

having been cited for similar infractions in the past, the company continues to

place workers in harm's way by allowing hazards to exist.”

OSHA said LM workers

did not have proper protective equipment for working with styrene. “Severe

chemical burns to the body were reported to the employer,” the agency said.

Repeat, Serious

Violations

In addition to the

willful violations, OSHA issued five repeat violations for alleged failure to:

- Provide adequate respirators “for conditions immediately dangerous to life or health”;

- “Purge or ventilate” the atmospheric hazards within a confined space;

- Prevent employee overexposure to styrene levels exceeding the time, weighted average and ceilings limits; and

- Implement engineering controls to ventilate the confined space.

Four serious

violations also were issued for allegedly failing: to:

- Provide appropriate personal protective equipment;

- Conduct effective confined space monitoring;

- Retrain employees when required; and

- Maintain an accurate count of entrants in permit-required confined spaces.

A repeat violation

exists when an employer has been cited for the same or a similar violation

within five years. Serious violations reflect a “substantial probability” of

death or serious injury from a hazard about which the employer knew or should

have known.

The company has 15

business days to accept or contest the violations.

OSHA Record

LM Wind Power,

founded in 1940 as a wood furniture company in Denmark, is the world’s largest

manufacturer of wind turbine blades, with 13 production facilities on three

continents. In April 2010, the company changed its name from LM Glasfiber.

The North Dakota

facility opened in 1999 and employs several hundred people.

LM has a history with

OSHA, with violations and allegations that include spray finishing hazards,

combustible materials, fall protection and respiratory issues, noise and dust.

These cases have been

closed:

·

In

2008, LM paid $17,400 in fines (reduced from $29,000) for four serious and one

repeat violation related to styrene exposure, lack of respiratory protection

and other violations at the Grand Forks facility.

·

In

April 2010, the company paid $1,500 (reduced from $6,000) for two serious

violations (reduced from four) and one other-than-serious violation at the same

facility.

·

Earlier

this month, the company paid $2,500 to settle one other-than-serious violation

(reduced from serious) at the plant.

·

The

company was also cited in 2009 for violations at its plant in McBain, MI.

The company also is

currently contesting several open cases involving the Grand Forks plant:

·

Last

July, a 42-year-old plant worker was fatally crushed between two pieces of

equipment. Witnesses said Joseph Francis Schaff, a father of two young sons,

was working about 10 to 12 feet up on a scissor lift when he was struck from

behind by a separate lift system that ran along rails fixed to the top of a

concrete wall.

LM is contesting

three serious and one willful violation and $92,000 in fines issued in that

case.

·

The

company is also contesting two citations issued in October 2008. That fine has

already been reduced to $850 from $2,975, and one serious violation has been

reduced to other-than-serious.

·

Finally,

the company is appealing two serious citations (reduced from three) and a

$3,000 fine (reduced from $7,875) issued in April 2007 for spray finishing

hazards and other issues.

Occupational

exposures to styrene vapor in a manufacturing plant for fiber-reinforced

composite wind turbine blades.

OBJECTIVES:

A utility-scale wind

turbine blade manufacturing plant requested assistance from the National

Institute for Occupational Safety and Health (NIOSH) in controlling worker

exposures to styrene at a plant that produced 37 and 42 m long fiber-reinforced

wind turbine blades. The plant requested NIOSH assistance because previous air

sampling conducted by the company indicated concerns about peak styrene concentrations

when workers entered the confined space inside of the wind turbine blade. NIOSH

researchers conducted two site visits and collected personal breathing zone and

area air samples while workers performed the wind turbine blade manufacturing

tasks of vacuum-assisted resin transfer molding (VARTM), gelcoating, glue

wiping, and installing the safety platform.

METHODS:

All samples were

collected during the course of normal employee work activities and analyzed for

styrene using NIOSH Method 1501. All sampling was task based since full-shift

sampling from a prior Occupational Safety and Health Administration (OSHA)

compliance inspection did not show any exposures to styrene above the OSHA

permissible exposure limit. During the initial NIOSH site visit, 67 personal

breathing zone and 18 area air samples were collected while workers performed

tasks of VARTM, gelcoating, glue wipe, and installation of a safety platform.

After the initial site visit, the company made changes to the glue wipe task

that eliminated the need for workers to enter the confined space inside of the

wind turbine blade. During the follow-up site visit, 12 personal breathing zone

and 8 area air samples were collected from workers performing the modified glue

wipe task.

RESULTS:

During the initial

site visit, the geometric means of the personal breathing zone styrene air

samples were 1.8 p.p.m. (n = 21) for workers performing the VARTM task, 68

p.p.m. (n = 5) for workers installing a safety platform, and 340 p.p.m. (n =

14) for workers performing the glue wipe task, where n is the number of workers

sampled for a given mean result. Gelcoating workers included job categories of

millers, gelcoat machine operators, and gelcoaters. Geometric mean personal

breathing zone styrene air samples were 150 p.p.m. (n = 6) for millers, 87

p.p.m. (n = 2) for the gelcoat machine operators, and 66 p.p.m. (n = 19) for

gelcoaters. The geometric mean of the personal breathing zone styrene air

samples from the glue wipe task measured during the follow-up site visit was 31

p.p.m. (n = 12).

CONCLUSIONS:

The closed molding

VARTM process was very effective at controlling worker exposures to styrene.

Personal breathing zone styrene air samples were reduced by an order of

magnitude after changes were made to the glue wipe task. The company used

chemical substitution to eliminate styrene exposure during the installation of

the safety platform. Recommendations were provided to reduce styrene

concentrations during gelcoating.

The Evolution of Infusion to Circumvent the Problems

Posed by Styrene Regulation

The use of the

resin infusion process has grown significantly in the 25 years since fiberglass

boatbuilder/composite materials distributor Seemann Composites (Gulfport,

Miss.) introduced SCRIMP (Seemann Composites Resin Infusion Molding Process). In Europe, manufacturers of marine and

industrial composites will have to look at infusion and other closed molding

processes, due to the increased regulation of styrene,” observes infusion

researcher John Summerscales, an associate professor of composites engineering

at the University of Plymouth (Plymouth, U.K.). Currently, styrene exposure

limits vary by country in Europe, from 20 to 100 parts per million (ppm), with

the U.K. maintaining the latter. However, in 2011, the European Chemical

Industry Council (CEFIC) proposed that the derived no-effect level

(DNEL) for worker inhalation exposure to styrene should be 20 ppm (over an

eight-hour, time-weighted average) and that this DNEL might be used to

harmonize styrene exposure limits across the European Union.

The American

Composites Manufacturers Assn. (ACMA) has responded to similar pressure in the

U.S. by proposing an occupational exposure limit (OEL) of 50 ppm, which it says

will mean “working toward a target eight-hour average exposure of approximately

35 ppm.”

Resin infusion is an

extremely effective way to meet these new limits. For example, during a 2009

National Institute for Occupational Safety and Health (NIOSH) walk-through

survey of the LM Glasfiber (now LM Wind Power) wind blade facility in Grand

Forks, N.D., the lowest personal breathing zone measurements for styrene were among

the 21 workers performing infusion, all at less than 5 ppm.

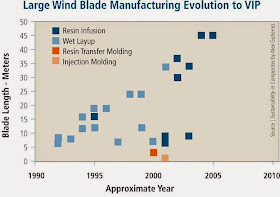

Indeed, wind blade

manufacturers migrated to resin infusion and other closed mold processes

between 2000 and 2005 (see Figure above), with production of large blades (length

>30m/98 ft) reportedly now split between infusion (65 percent) and prepreg

(35 percent). Some industry pundits predicted that the use of prepreg would

increase with the quest for automation through automated tape laying (ATL)

machines. However, ATL has been limited to spars so far, and industry experts

like Steve Nolet, TPI Composites’ (Scottsdale, Ariz.) principal

engineer/director of innovation, doubt its ability to match manual placement

rates of 1,500 kg/hr (3,307 lb/hr) and targeted finished product costs of $5/lb

to $10/lb.

INCREASING USE OF

VOLATILE ORGANIC CHEMICALS IN COMPOSITES POSES RISKS TO CONSUMERS FROM

OFF-GASSING

VOCs

(volatile organic compounds) are blamed for damaging the earth's ozone

layer and thereby contributing to global warming. These chemicals are also

dangerous to human health. As a result of these concerns, the last twenty years

have seen a concerted effort by governments to control their release into the

environment.

The

Importance of Control

The

human body reacts to VOCs when breathed in. Some of them cause dermatitis and styrene

is 'reasonably anticipated to be a human carcinogen' according to the US

National Toxicology Program. However,

there is evidence that disputes this. We

believe that there individuals are more sensitive than others and this could explain

the “differences” in the toxicity or carcinogenicity of these compounds.

Most

advanced countries require that any production facility which uses VOC-based

resins in any significant quantity has to have an emission control system as

well as providing clean breathing air and protective suiting, gloves and

goggles for its workers.

Industry

too is striving to minimize the use of these chemicals. Styrene and other

esters can leach out into the atmosphere after the composite has been

manufactured, and this is known as off gassing. Automobile manufacturers have

recognized a condition which they call 'sick car syndrome' and construction

firms too recognize 'sick house syndrome'. Customers don't like these fumes

coming from the products they buy.

Scale

of the Problem

VOCs

make up a significant portion of traditional resin formulations used for

composites. Typically, a lay-up which requires 10 gallons of conventional vinyl

ester resin would put 30 lbs of VOCs into the air. A large bathtub manufacturer

could produce 250,000 tons per year of styrene fumes.

In

the US, since 2006, those firms that produce more than 10 tons of volatile

organic compound (VOC) emissions per year have to meet the Environmental

Protection Agency's Maximum Achievable Control Technology (MACT).

Solutions

There

are a number of solutions to the problem:

Chemistry

- Resins with reduced VOC content. These are known as low-HAP resins (low Hazardous Air Pollutant). Most of these resin formulations offer a range of 32% to 37% styrene content.

- New resins with zero VOC content. So-called green epoxy resins are versatile and are cited as a direct replacement for regular resins even in aerospace applications. These are available as one- and two-part formulations.

Physical

Plant and Process Changes

- VOC abatement equipment requires significant capital investment. Typical solutions involve incineration of fumes. A bathtub manufacturer might incinerate their ¼ million tons of styrene fumes, but for the plant to do that is well beyond the resources of most small and medium sized composite manufacturers.

- Low emission production uses non-atomized spraying for open molding. Closed-mold resin transfer molding and closed die injection for pultrusion provide direct physical constraint of emissions.

Most

smaller manufacturers combine low- or zero-VOC resins with the low emission

production techniques.

Post

Production Emissions

'Bake-out'

is now being used by builders before occupancy of a new building. This

process is designed to drive the VOCs out of the construction materials by

increasing the temperature in the building to as much as 110 deg. F. Outdoor

air exchange is maintained so that hazardous gases are emitted from the

building. In commercial buildings this process is carried out with all

furnishings in place as composites and plastics are heavily used in the

interior. The procedure takes up to two weeks and is obviously performed prior

to occupancy.

At

present there do not appear to be any automobile manufacturers who use

bake-out, though it would seem that it would be something that the component

manufacturers (e.g. composite dashboard assemblies, carpeting and so on) could

carry out.

VOC

Controls - the Future

Unintended

consequences are often a result of legislation, and now some larger

manufacturers who have invested heavily in VOC abatement are finding that their

systems are so efficient that they can use resin formulations with higher VOC

content than they used before. That is certainly not what the legislators

intended.

Demand

is driving researchers to develop 'greener' resins because it is a certainty

that controls will tighten. Resins based on recycled raw materials are now

being marketed.

It

is inevitable that low- and zero-VOC resins will become more widely used as

production volumes increase and raw material prices fall.

Metropolitan Engineering, Consulting & Forensics

(MECF)

Providing

Competent, Expert and Objective Investigative Engineering and Consulting

Services

P.O. Box

520

Tenafly,

NJ 07670-0520

Tel.:

(973) 897-8162

Fax:

(973) 810-0440

E-mail:

metroforensics@gmail.com

Web

pages: https://sites.google.com/site/metropolitanforensics/

https://sites.google.com/site/metropolitanenvironmental/

We are happy to announce the launch of our twitter account. Please make

sure to follow us at @MetropForensics or @metroforensics1

Metropolitan appreciates your business.

Feel free to recommend our services to your friends and colleagues.